Generative AI, Virtual Twin, and intelligent automation to accelerate design, engineering, and manufacturing.

Introduction

CATIA 2026X marks a turning point in the way industrial products are designed and developed. Generative engineering, artificial intelligence, and the Virtual Twin are now integrated across disciplines, improving efficiency and decision-making from the earliest phases of a project.

This new generation is built on three key pillars:

- Augmented Engineering: AI as the engineer’s assistant

- Space of Possibilities: rapid exploration of alternatives

- Fit for Use by Design: robust, manufacturable products from the start

To make navigation easier, the main innovations in CATIA 2026X are structured into four major areas, allowing readers to go directly to the section of greatest interest:

- Design and styling

- Engineering

- Systems engineering

- Buildings and infrastructure

Design & Styling: augmented creativity and faster decisions

CATIA 2026X strengthens the creative environment by integrating advanced modeling, generative AI, immersive experiences, and real-time collaboration, enabling design teams to work with greater agility and precision.

Creative Portfolio Board & Inspiration

The new Creative Portfolio Board introduces ready-to-use templates that streamline the creation of mood boards, brainstorming sessions, and collaborative spaces. This accelerates the conceptual phase and ensures visual consistency from the very beginning of the project.

In addition, AI-based image generation (Beta) makes it possible to turn text, sketches, or reference images into realistic visuals, helping ideas materialize quickly and aligning all teams in early stages.

Advanced Creative and Conceptual Design

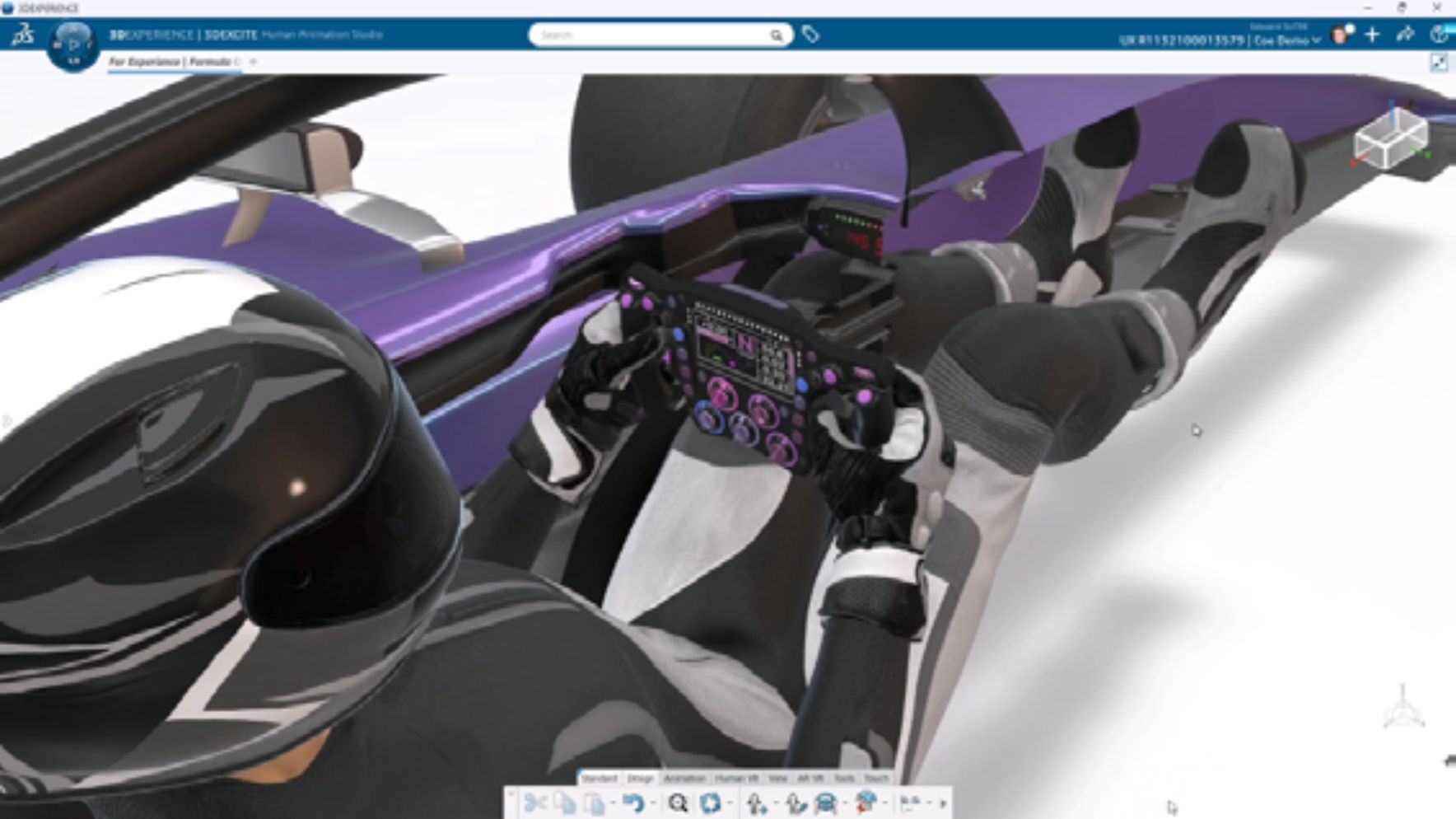

Enhancements to subdivision surfaces and mesh tools enable the creation of complex, high-quality geometries, especially relevant for industrial design and automotive applications. These capabilities are complemented by advanced Human Experience Design features, incorporating a human Virtual Twin and gesture tracking in virtual reality environments.

This allows teams to evaluate ergonomics, interaction, and usability before products physically exist.

Surface Modeling and Sculpting for Class-A Quality

The ICEM Design eXperience evolves to facilitate the creation of Class-A surfaces with greater control and consistency. New guided checks, robust symmetries, and curve extrapolation capabilities help achieve high surface quality standards while reducing iterations and rework.

All of this is delivered through a more streamlined, productivity-focused interface, shaped by direct feedback from real production environments.

Reverse Engineering: from the real world to the virtual

CATIA 2026X significantly enhances reverse engineering workflows, making it easier to convert scanned models into precise digital geometry. Rapid symmetry detection and automatic regeneration of characteristic edges preserve original design intent and accelerate the transition from the physical to the digital world.

Generative Design and Visual Scripting

Visual Scripting for generative design enables automation of complex design sequences, organization of modular structures, and controlled exploration of multiple variants. Improved navigation and graph modularity simplify the management of complex models.

In the near future, automatic generation of 3D meshes from 2D images will further expand possibilities in early design phases.

Immersive Visualization and collaborative design

Immersive visualization takes a major step forward thanks to:

- Ultra-fast opening of large 3D assemblies

- Capturing comments directly on the model

- High-performance interactive rendering

- Collaborative reviews using Apple Vision Pro on a shared Virtual Twin

In addition, synchronous multi-user modeling allows multiple engineers to work simultaneously on the same design, regardless of location.

Engineering: more speed, more control, less complexity

New Welcome Page

The new Welcome Page centralizes access to applications, recent data, and new-feature content, improving the user experience and reducing unproductive time from the first interaction with the platform.

Modular Design Fundamentals

CATIA 2026X introduces modular design as a core capability. Teams can create self-contained, reusable modules that automatically connect across projects, applicable to surfaces, solids, and generative scripts alike.

This approach improves model robustness, promotes reuse, and enables rapid adaptation to changing requirements.

Command Intelligence: AI as the engineer’s copilot

The new Command Intelligence leverages artificial intelligence to anticipate user intent and suggest the most appropriate command in each context, based on best practices and expert knowledge.

This reduces time spent searching for commands, simplifies onboarding for new engineers, and can deliver productivity gains of up to 30%.

Lightspeed Virtual Twin Visualization

Virtual Twin visualization becomes virtually instantaneous, even for very large assemblies. Engineers can work with lightweight representations, select subsets, and make context-aware decisions without compromising model accuracy.

Generative Assembly and Engineering for Manufacturing

Generative Assembly enables automatic creation of assemblies from parts and subassemblies, predicting mechanical interfaces and enabling downstream validations such as kinematic analyses or functional tolerances.

Engineering for Manufacturing simplifies the creation and management of tolerances, annotations, and GD&T, supporting concurrent work and more agile handling of 3D specifications and 2D documentation.

Systems Engineering and software-defined products

Model-Based Systems Engineering (MBSE)

CATIA 2026X provides full support for the new SysML v2 standard, with bidirectional synchronization between textual and graphical models. Capabilities for safety-by-design engineering are also strengthened, aligned with industry standards and methodologies such as FMEA.

Cyber Systems Simulation

The new Sustainable Supply System Library, based on Modelica, enables simulation of years of operation in seconds, identifying domino effects and edge-case scenarios that traditional indicators fail to detect.

Software-Defined Products

CATIA strengthens the development of software-defined products through bidirectional workflows between models and code, integrating sector-specific protocols for industries such as aerospace and defense, and ensuring consistency from system architecture through final implementation.

Buildings & Infrastructure: faster, safer, and better-coordinated projects

CATIA 2026X expands its capabilities for buildings and civil infrastructure, enabling:

- More accurate modeling of walls, openings, doors, and windows

- Automated multidisciplinary coordination

- Advanced tools for road design and complex interchanges

These enhancements help deliver projects that are safer, better coordinated, and aligned with strict regulations and demanding schedules.

Conclusion: a new way of thinking about engineering

CATIA 2026X is not just a functional evolution, but a shift in mindset. The combination of generative AI, Virtual Twin, intelligent automation, and web-based architecture enables companies to tackle today’s complexity with greater control, speed, and quality.

Natively integrated into the 3DEXPERIENCE platform, CATIA 2026X empowers design, engineering, and manufacturing teams to turn innovation into a real competitive advantage.

Want to learn how to apply CATIA 2026X capabilities to your engineering processes?

comunicacion@cadtech.es – 800 007 177