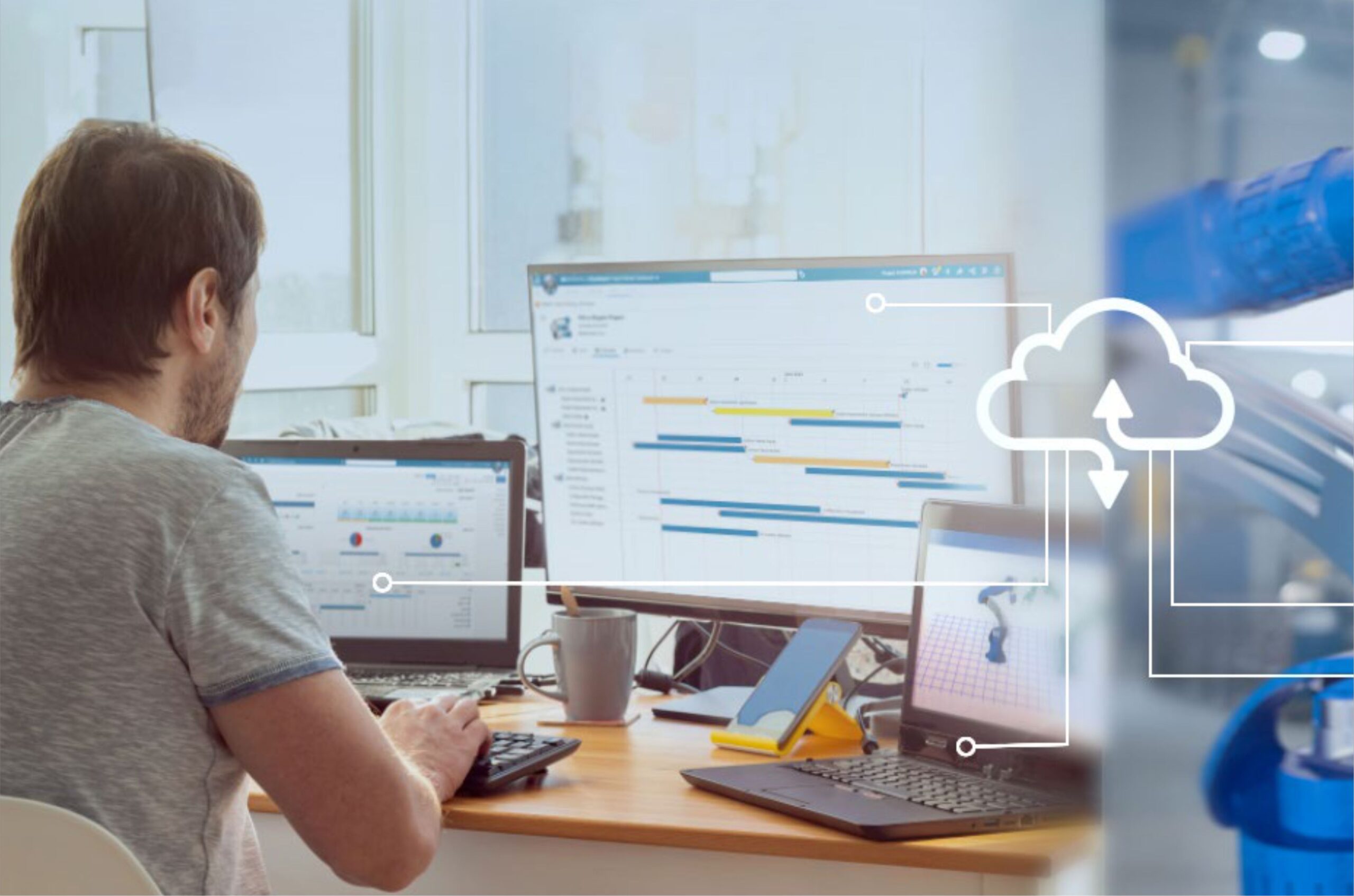

Digital manufacturing integrates advanced technologies to plan, simulate, and optimize production processes in a virtual environment. This approach allows companies to anticipate and address challenges before physical implementation, reducing costs and improving operational efficiency.

Digital Manufacturing

Additionally, by connecting design with production, a smooth transition from product conception to manufacturing is ensured. This accelerates time-to-market and enables more agile and informed decision-making.

Key Process Areas of Digital Manufacturing

Digital manufacturing encompasses several fundamental areas:

Process Planning

Defining and optimizing production sequences, ensuring efficiency and quality at every stage.

Operations Simulation

Creating virtual models of production lines to identify bottlenecks and improve workflow.

Machine Programming

Development and validation of programs for CNC machines and robots, ensuring precision and reducing setup times.

Ergonomics Analysis

Assessment of working conditions to enhance operator safety and comfort, thereby increasing productivity.

Resource Management

Efficient allocation of materials, tools, and personnel, optimizing resource use and reducing waste.

The Value of Digital Manufacturing in Industry

Industrial companies face constant production challenges, such as lack of system integration, version errors, and information loss. Digital manufacturing enables these issues to be addressed efficiently:

Full System Integration

Unifies production information in a digital environment, eliminating data silos and ensuring all departments work from a single source of truth. This improves consistency, reduces duplication, and optimizes decision-making.

Full Traceability and Regulatory Compliance

Provides detailed tracking of every step in the manufacturing process, ensuring regulatory compliance, facilitating audits, and improving real-time quality control.

Accurate Version Management

Maintains strict control over production programs and processes, preventing confusion and ensuring that work is always done with the most up-to-date information.

Information Security and Preservation

Securely stores all production data, reducing the risk of losing critical information and enabling immediate recovery when needed.

DELMIA 3DEXPERIENCE: Transforming Digital Manufacturing

Digital manufacturing enables the modeling, simulation, and optimization of production operations in a collaborative environment, ensuring a seamless connection between design and manufacturing. With advanced tools, companies can anticipate challenges, improve efficiency, and ensure more agile and adaptive execution of their production processes.

DELMIA 3DEXPERIENCE takes this approach to the next level, providing an integrated ecosystem for production planning and management. Discover here how DELMIA can transform your operations and optimize your processes.