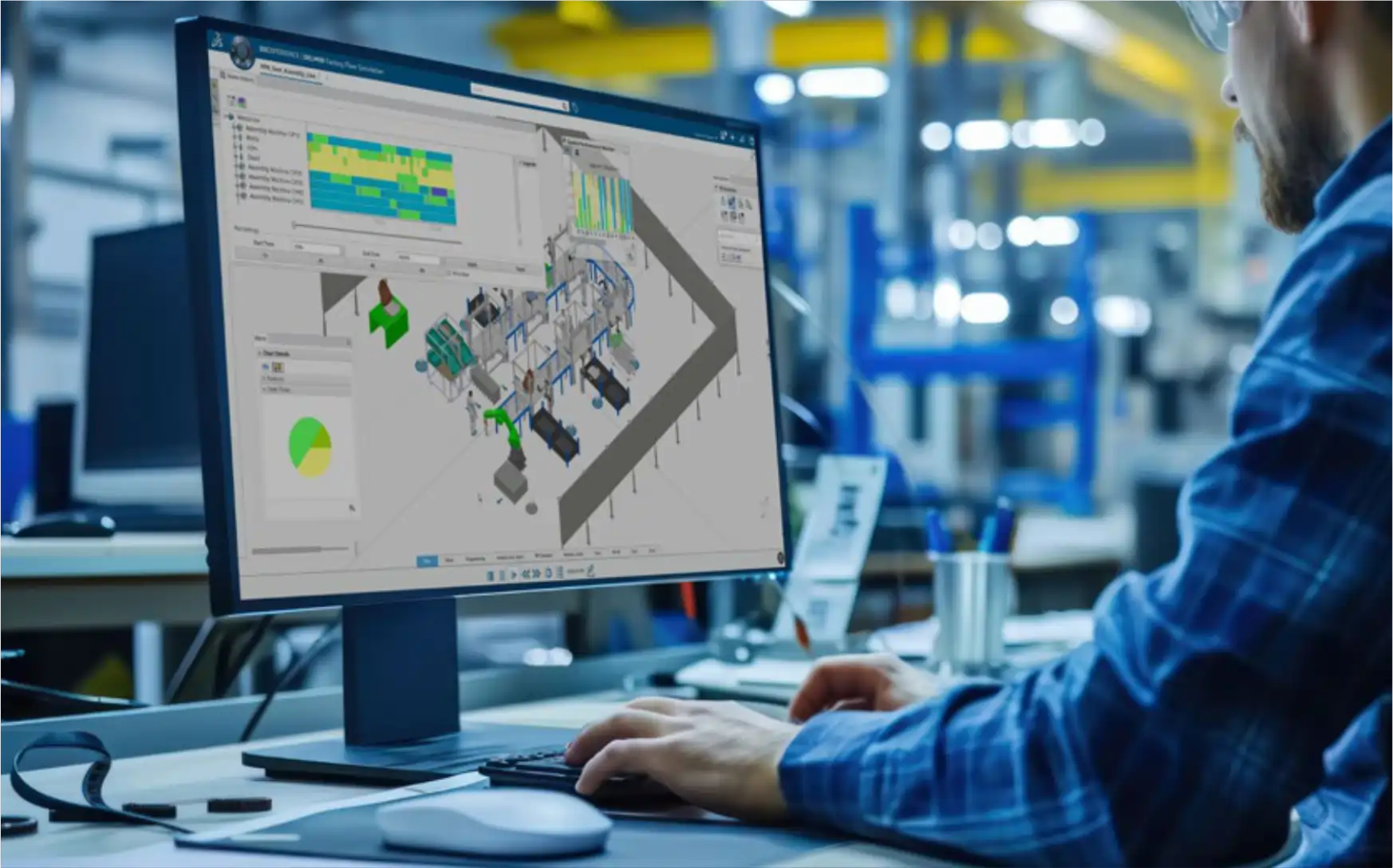

DELMIA 3DEXPERIENCE is a comprehensive solution that connects the virtual world with the real world, allowing companies to plan, simulate, and optimize their manufacturing operations in a collaborative environment.

DELMIA 3DEXPERIENCE

Digitize your manufacturing, optimize every process.

Integrated into the 3DEXPERIENCE platform, DELMIA offers advanced tools for digital manufacturing, robotics, and machining, facilitating the digital transformation of production processes.

Key Benefits of DELMIA 3DEXPERIENCE:

DELMIA provides tools and methodologies to plan and optimize production processes, from design to execution. It allows for the creation of digital models that virtually simulate products, processes, and factory operations, facilitating their validation and improvement before physical implementation. This results in greater efficiency, cost reduction, and minimization of production errors.

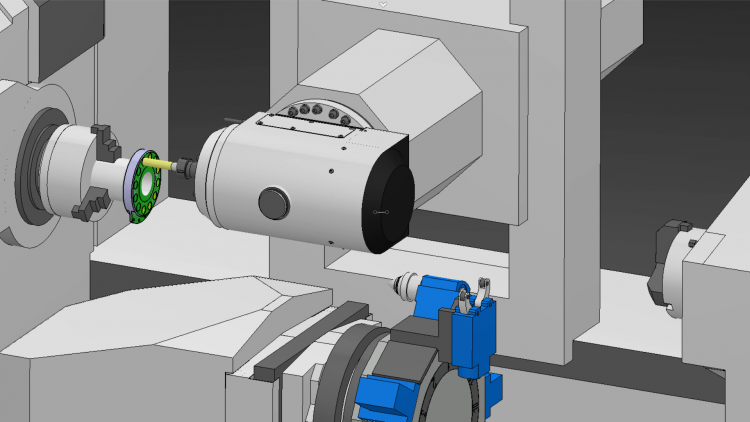

DELMIA offers tools for CNC programming and the optimization of machining processes. It allows for the simulation of machining operations, optimization of tool paths, and validation of processes before execution, ensuring precision and efficiency in part manufacturing. This contributes to reducing cycle times, improving product quality, and lowering operating costs.

Being available on the 3DEXPERIENCE platform in the cloud, DELMIA enables more agile planning and execution of manufacturing operations. Cloud integration facilitates real-time collaboration between teams, remote access to tools and data, and faster solution deployment. This results in greater flexibility, scalability, and efficiency in manufacturing operations management.

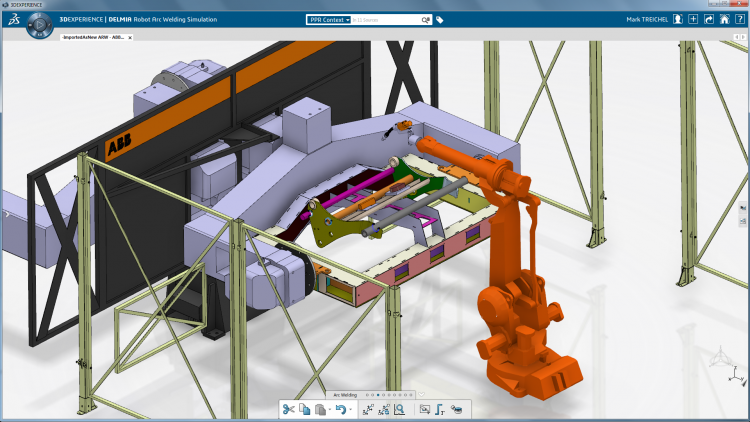

The solution offers advanced capabilities for robot programming and simulation in production environments. It allows for defining robotic work cells, programming and optimizing robots, and fully simulating the manufacturing environment and product flow. This facilitates the validation of robotic programs and the optimization of operations before their implementation on the shop floor, reducing downtime and improving productivity.

DELMIA allows for precise production planning and optimization, managing capacity, resource allocation, and process synchronization based on demand and operational constraints. Thanks to its ability to simulate different scenarios and adjust plans in real time, it helps to improve efficiency, reduce waiting times, and maximize resource utilization. With intelligent and adaptable planning, companies can respond agilely to changes in production and ensure optimal execution.

DELMIA 3DEXPERIENCE: Transforming Manufacturing

Avoid delays and unforeseen events with intelligent planning that adjusts production capacity in real time, ensuring on-time delivery.

Integrate design and manufacturing with advanced simulations that eliminate errors before production, reducing waste and adjustment times.

From robot programming to CNC process execution, automate key operations to increase precision and efficiency.

With real-time data and predictive analytics, optimize resource allocation and minimize downtime on the production line.

Connect engineering, production, and logistics teams in a collaborative environment, ensuring that everyone works with the same updated information.

With DELMIA 3DEXPERIENCE, production becomes predictable, efficient, and fully optimized.

What once was uncertainty is now total control.

Discover how DELMIA 3DEXPERIENCE can transform your manufacturing.

Current Events and Trends in the DELMIA 3DEXPERIENCE Environment

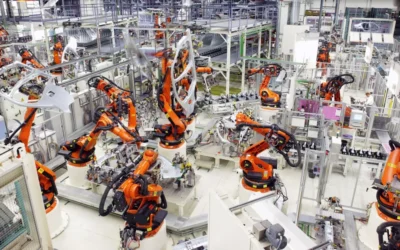

KUKA integrates 3DEXPERIENCE into its digital ecosystem to boost efficiency in robotics and automation

3DEXPERIENCE is being incorporated into KUKA’s mosaixx digital ecosystem, making access to its solutions easier for industrial customers. The collaboration will enable robotics and automation companies to develop more efficient and adaptable solutions to...

CT successfully completes the MultiFAL project using the 3DEXPERIENCE Platform in the cloud

After an ambitious four-year challenge, the MultiFAL project, funded by the European Union, is entering its final phase with excellent results for the aircraft assembly industry: the development of a full-scale automated plant system for joining thermoplastic...