Globalization has led many industrial companies to operate production plants distributed across different countries or regions. This model offers competitive advantages, but it also poses a major challenge: how to keep all teams and processes aligned without losing efficiency, quality, or control.

When each plant works with disconnected systems, problems multiply:

- Delays due to lack of access to the latest design versions.

- Different processes at each location, making standardization difficult.

- Challenges in coordinating production, quality, and logistics.

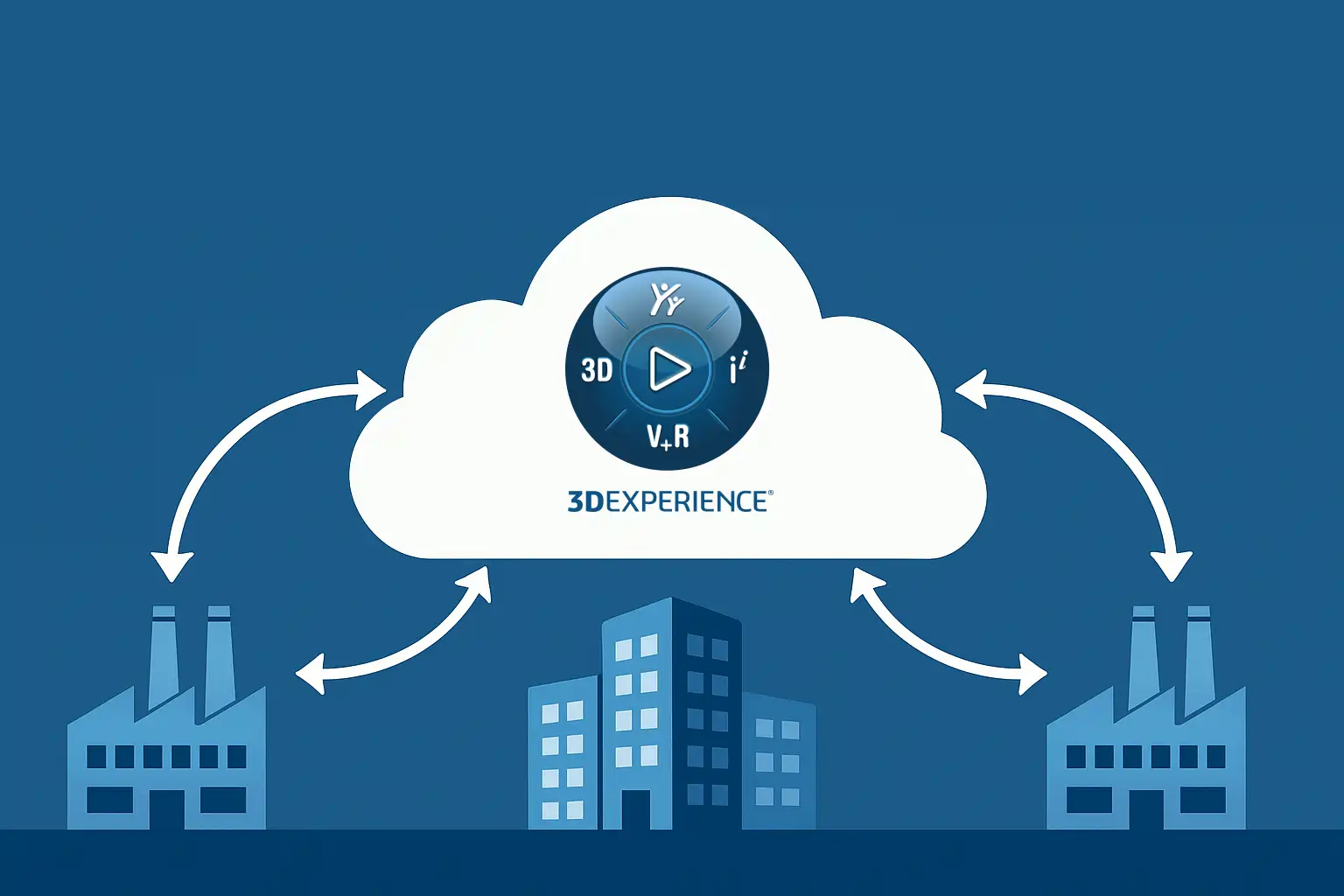

The answer lies in the cloud. With 3DEXPERIENCE in the cloud, companies can unify their information and processes on a single global platform, accessible anytime and anywhere.

A single source of truth for everyone

The greatest value of 3DEXPERIENCE in the cloud is that all teams work on the same information in real time.

- Engineers in Germany, operators in Mexico, and quality managers in Spain access the same models, programs, and data without duplication.

- Every change is automatically recorded and synchronized across all plants.

- The risk of a plant manufacturing with outdated documentation is eliminated.

This “single digital thread” ensures that work flows smoothly, without interruptions, and with complete consistency across locations.

Standardization and global control

A company with multiple plants needs homogeneous processes to ensure that quality and deadlines are met consistently.

With 3DEXPERIENCE in the cloud, it is possible to:

- Define standard procedures that all plants automatically follow.

- Monitor in real time the status of each project, batch, or order.

- Detect and correct deviations before they impact the end customer.

The result is a more robust, controlled global production with less variability.

Scalability without IT complications

One of the biggest obstacles to international expansion is the cost and complexity of IT infrastructure. With the cloud, that barrier disappears.

- There is no need for local servers or on-site maintenance at each plant.

- New sites can be integrated into the platform immediately.

- Updates are automatic, and the latest version is always in use.

This allows the company to grow and adapt without technological penalties.

Tangible benefits for companies with multiple plants

Adopting 3DEXPERIENCE in the cloud delivers immediate benefits:

- Global synchronization: everyone works with the same information in real time.

- Standardized processes: consistent quality and efficiency across all sites.

- Fast scalability: new plants are integrated without complex IT investments.

- Reduced errors and delays: less rework and greater schedule reliability.

Ultimately, the cloud turns the complexity of coordinating distributed plants into a competitive advantage, aligning teams anywhere in the world and ensuring that innovation reaches the market faster.

Conclusion

Companies operating across multiple locations can no longer afford information silos or uncoordinated processes. The future is global, and management must be global as well.

With 3DEXPERIENCE in the cloud, each plant becomes part of a perfectly integrated whole, working with the same information and processes, regardless of where it is located.

Because in the era of globalization, the cloud is not just an option: it is the only way to compete.

Do you want to discover how to align all your plants on a single platform?

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177