Faced with increasing demands, Aciturri implemented the Ready for Rate solution to improve project planning, cutting aerostructure delivery times in half and strengthening customer trust.

Designing and manufacturing the aerostructures of the future

When Ginés Clemente opened a small machining workshop in the Spanish city of Miranda de Ebro in 1977, he could hardly have imagined that it would one day become a key company in producing some of the most advanced aircraft in the world.

As a Tier 1 reference supplier for original equipment manufacturers (OEMs), Aciturri develops structural components under a design-to-build approach for commercial and defense aircraft such as the Airbus A350, Boeing 787, Boom Supersonic Overture, and Embraer KC390. The company is also expanding into new areas such as electric mobility, designing and producing various components for eVTOL aircraft, including wings for the Brazilian company Eve Air Mobility.

With 40 production plants spread across Spain, France, Morocco, and Brazil—each specializing in specific areas such as composites, metallics, assemblies, etc.—Aciturri selects the location of each project based on the required specialization. It then analyzes the physical requirements involved in working with large components.

“We start by analyzing geometries, manufacturing processes, certifications, machine specifications, and other constraints to decide where to produce,” explains Eduardo Cid, Head of Industrialization at Aciturri. “And since some parts reach 20 meters in length, it’s essential to ensure we have enough space for the equipment and the people working around it. This requires a very detailed layout analysis.”

Today, Aciturri has perfected this layout analysis to the level of an art, thanks to advanced digital simulation solutions that allow the company to present and plan projects with great speed and precision.

Precise planning for demanding projects

Given the level of planning required to manufacture a new component for an aircraft as complex as the Boeing 787, the company realized it needed the right solution to accomplish it.

Seeking a 3D simulation solution that would help it plan better, handle complex demands, and win new contracts, Aciturri adopted Dassault Systèmes’ cloud platform as the best option for its needs. By choosing a cloud solution, implementation was fast, and access to Dassault Systèmes’ user communities allowed the engineering team to receive continuous support from industry experts.

“We have been using CATIA V5 for many years, so we already had an enormous database with 3D models of parts, tools, machines, industrial resources, etc.,” says Cid. “We wanted to manage all that data and those processes in a single environment, ensuring that everyone worked with the most up-to-date designs and making change management easier. That’s why we decided to migrate to the 3DEXPERIENCE® platform.”

Dassault Systèmes’ developers provided excellent support. “When a problem arises, I can post a question in the user community, and I get a response within a few hours,” Cid says. “It’s exceptional.”

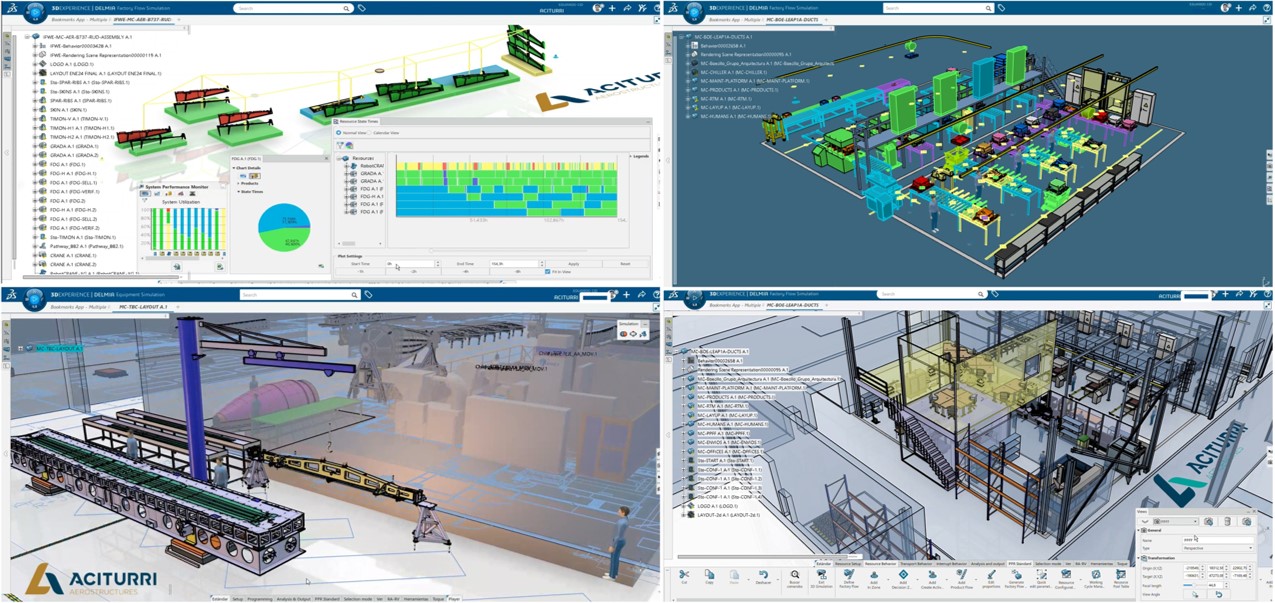

Meanwhile, the implementation of DELMIA has enabled a fundamental transformation in project planning. Aciturri can now build an accurate virtual twin of its plants, allowing it to optimize and validate processes digitally before implementing them in the real world.

“We create a 3D representation of the plant, not only adding parts, machines, and operators to account for space but also connecting all those resources to estimate times and calculate precisely how many components we can deliver in a specific period,” Cid explains.

Although the aerospace sector has some degree of automation, many processes are still manual. People are not machines, so variability must be considered to estimate times realistically.

“We run discrete event simulations using the factory flow,” Cid explains. “And we repeat that simulation many times because we use a stochastic approach to introduce variability. Finally, we calculate the mean and the standard deviation. That allows us to provide estimates like: ‘Our minimum capacity is 96 and the maximum is 102, with a 95% confidence level.’”

Reducing delivery times by half and earning customer trust

Thanks to more efficient and accurate processes, Aciturri has managed to cut the time required to complete a project in half.

“In the aerospace industry, it used to be common to assume that industrializing a new work package—from design to prototype and final delivery—took about two years,” says Cid. “That was due to many assumptions: whether there was enough space, capacity, whether our Excel formulas were reliable… Thanks to DELMIA, we now make faster, better, and more precise decisions. As a result, we have reduced the typical delivery timeline to one year.”

With DELMIA, Aciturri can create animated models to present to customers, showing production processes, complete workflow simulations, and even the estimated capacity of plants. This has helped them earn customer trust.

“Customers can see that we have thoroughly analyzed their requirements, simulated processes, evaluated scenarios, and reached an optimal solution,” says Cid.

The value of this approach became clear in a meeting with a customer.

“They invited me at the end of a long meeting where everyone was tired,” he recalls. “My one-hour presentation became two minutes. I simply showed the animation of what we could deliver. That convinced the customer. That’s when I understood the true value of DELMIA: I realized we had chosen the right path.”

Preparing the path for the next steps

As competition intensifies and customers demand more, Aciturri continues working to optimize its processes. It currently uses multiple systems and tools, which complicates data integration and standardization. But soon it will unify all its information on the 3DEXPERIENCE platform.

“We are deploying the 3DEXPERIENCE platform as our main product lifecycle management (PLM) solution,” says Cid. “With ENOVIA, we will be able to centralize product and data management, which will not only save time when transferring information to DELMIA, but will also provide greater visibility and transparency across the entire organization.”

With a workforce of 2,800 employees—expected to double before the end of the decade—this transformation will be key to facing the next steps and supporting the sector’s growth.

Learn more about the solution Ready for Rate

About Aciturri

Headquartered in Spain, Aciturri is a Tier 1 supplier specializing in complex aerostructures. The company has extensive experience, particularly in the development of lightweight components in both composite and metallic materials. Aciturri is a founding member of Clean Aviation, the leading public-private initiative in the European Union for developing new aeronautical technologies.

More information at: https://www.aciturri.com

Dassault Systèmes and CADTECH support Aciturri on its path toward a more efficient and competitive industry.

Oficial customer storie available on the Dassault Systèmes website

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177