The California startup Pivotal is transforming air mobility with Helix, its innovative eVTOL (electric vertical takeoff and landing aircraft). To bring this concept to market with scalability and safety guarantees, the company has relied on Dassault Systèmes’ 3DEXPERIENCE Platform as its unified environment for design, engineering, and manufacturing.

Flying has never been so accessible

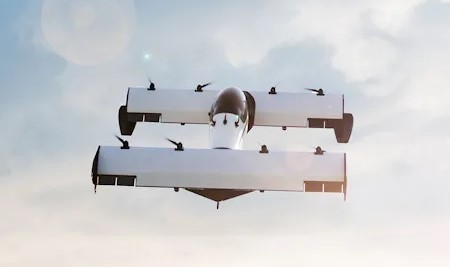

Helix is a compact eVTOL, about the size of a small car, that allows you to fly without needing a pilot’s license. Its innovative design eliminates the complexity of articulated wings: the entire structure rotates to take off or land, offering a safe, simple experience perfect for short trips of up to 30 km over lakes, forests, or rural areas.

Behind this revolution is Marcus Leng, founder of Pivotal, who built his first prototype in a basement and has accumulated more than 10,000 miles of flight to perfect the aircraft. Today, Pivotal has not only opened pre-orders in the U.S. but is also preparing to deliver its first units in 2025.

Unlike aircraft with tilt-wing or tilt-rotor designs, the Pivotal Helix achieves vertical takeoff and landing by rotating the entire aircraft.

(Image © Pivotal)

From idea to production on a single platform

To manage the transition from design to mass production, Pivotal adopted the 3DEXPERIENCE Platform, which allows it to integrate into a single collaborative environment the design of lightweight composite structures with CATIA, the planning and control of internal manufacturing processes with DELMIA, and the management of data and changes throughout the entire product lifecycle with ENOVIA.

Innovate with less weight, fewer parts, and more performance

The design of Helix minimizes mechanical complexity: no articulated wings or moving engines. This enables a lighter, more reliable, and easier-to-maintain structure. CATIA’s composite design module has been key to optimizing the carbon-fiber frame, simplifying calculations and adaptations.

In addition, the platform allows Pivotal to develop its battery management system in-house, which is critical to extending range and ensuring consistent performance. As market needs evolve, the company continues to invest in lighter technologies, higher-density energy solutions, and advanced thermal management.

Ready to grow… without losing control

With the help of DELMIA, Pivotal has managed to reduce assembly times by up to 30%, optimizing every production step from planning to shop-floor work instructions. This total integration allows designs to be modified without redoing processes from scratch, maintaining agility in manufacturing.

Their commitment to safety and training also stands out: although a pilot’s license is not required, users must complete a rigorous training program. All development—from requirements to delivery—is designed with the goal of minimizing waste, energy consumption, and risks.

Beyond personal use

The future of Helix is not limited to leisure. Pivotal is exploring applications in public and defense sectors, such as medical emergencies, rescue operations, or logistical support in hard-to-access areas. All of this will be possible thanks to the extended use of simulation and analysis tools within the 3DEXPERIENCE platform, a key component of its long-term strategy.

As Pivotal continues refining its technology and expanding its operations, it plans to leverage the potential of Dassault Systèmes’ simulation and analysis tools.

(Image © Pivotal)

About Pivotal

Pivotal is a startup based in Palo Alto (California), specialized in the design and manufacturing of lightweight eVTOLs. Known for the BlackFly, the first ultralight eVTOL on the market, the company has spent more than 12 years evolving its technology and rotary aircraft architecture. Helix represents the most mature version, designed for consumers, public services, and defense applications.

More information: www.pivotal.aero

Read the full case study on the Dassault Systèmes website here.

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177