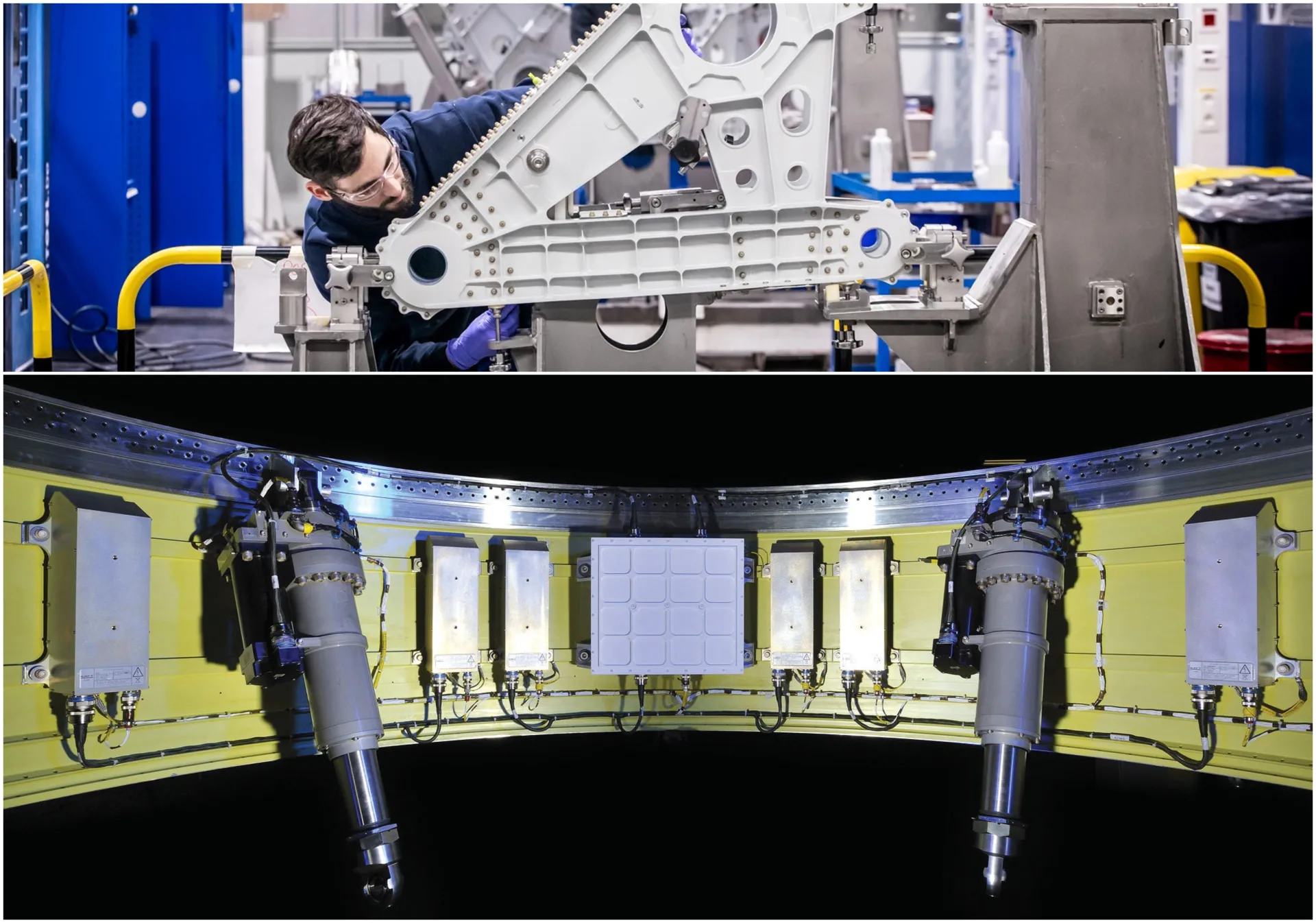

Actuators that make flight possible. At the heart of any aircraft, actuation systems play a fundamental role: from landing gear to ailerons, including brakes and doors, these systems enable precise, reliable, and safe maneuvering.

With more than a century of experience, SABCA (Société Anonyme Belge de Constructions Aéronautiques) has established itself as one of Europe’s leading companies in actuation systems for civil, military, and space aerospace applications. Its components are found in Airbus aircraft, Arianespace launchers, ESA missions, and Lockheed Martin aircraft.

The challenge: unifying processes in a single source of truth

Until recently, SABCA worked with multiple systems disconnected across engineering, manufacturing, and production. Each change involved long validation times and a high risk of errors.

With the goal of overcoming these barriers, the company committed to a long-term digital transformation based on Dassault Systèmes’ 3DEXPERIENCE Platform, where it now centrally manages its eBOMs and mBOMs, both on-premise and in the cloud.

“It was crucial to choose a next-generation solution. We needed a scalable platform that would support us for the next 10 years,”

Miguel Laduron, CIO of the Orizio group, to which SABCA belongs.

Connecting engineering and production from the design stage

Thanks to the integration of processes in 3DEXPERIENCE, SABCA’s teams collaborate more efficiently, aligning design, manufacturing engineering, and production from the earliest stages of projects. This allows them to accelerate the development of complex assemblies, involve suppliers sooner, and optimize their resources.

“One of our strengths is managing processes in parallel. The platform allows us to do this faster and more efficiently,”

Marten Venmans, SABCA’s Engineering Director.

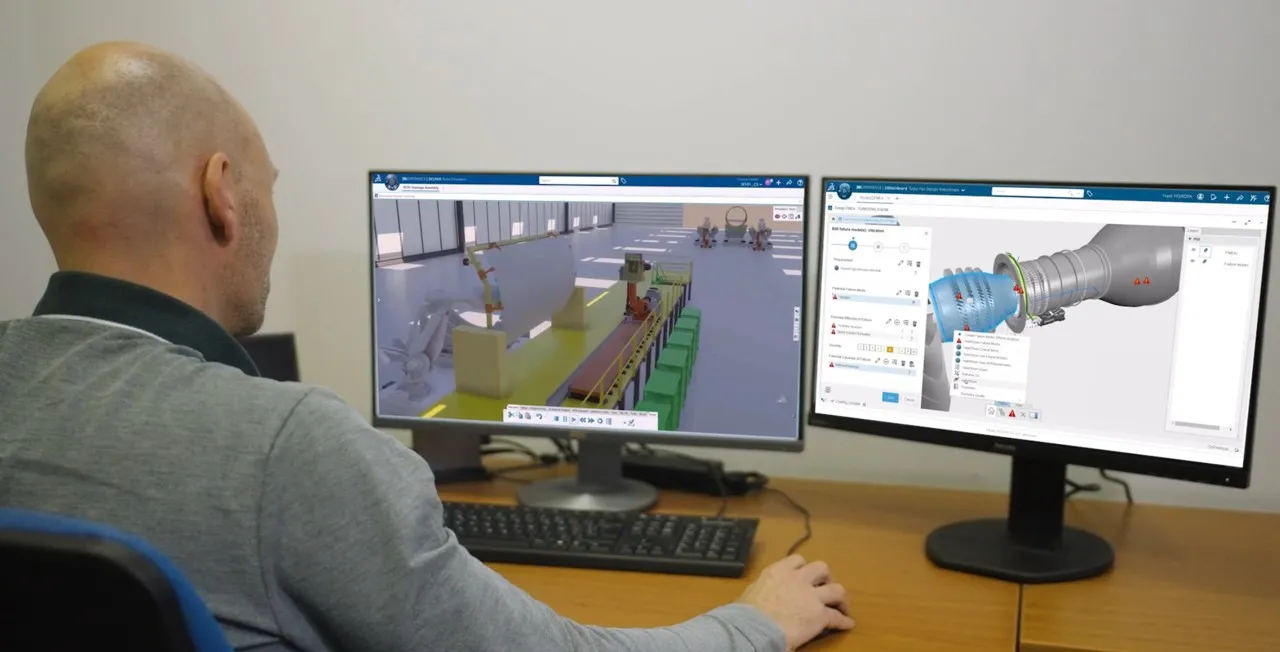

The next step: virtual twin and smart manufacturing

SABCA is already exploring the potential of the virtual twin to simulate plants and operations before moving to the physical phase. This approach allows them to plan more accurately, anticipate errors, and increase their production capacity.

“The virtual twin will be a cornerstone of our operations, comparing what was planned with what actually happens on the shop floor to improve each iteration,”

Miguel Laduron.

Committed to a more sustainable future

Aligned with the sector’s objectives, SABCA is developing new electric actuators that are lighter and more efficient than traditional hydraulic ones. This technology, already validated in space launchers such as Ariane 5 and Vega, is now being adapted to commercial aircraft together with Airbus.

About SABCA

Present in Brussels, Louvain-la-Neuve, Lummen, and Casablanca, SABCA is a key player in the European aerospace industry. Its expertise ranges from complex structures to actuation systems, covering the entire product lifecycle for the civil, space, and military sectors, as well as autonomous solutions for industrial applications.

More information: www.sabca.be

Read the full case study on the Dassault Systèmes website here.

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177