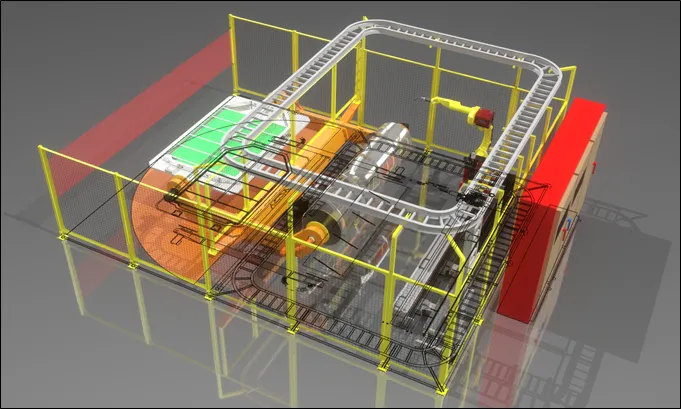

DELMIA Robotics, part of Dassault Systèmes’ 3DEXPERIENCE platform, provides advanced solutions for programming, simulation, and validation of robotic systems in manufacturing environments. Its approach enables the design and optimization of robotic cells before implementation, reducing costs and improving productivity.

DELMIA Robotics

Automation and robotic precision

Thanks to its simulation tools, DELMIA Robotics helps anticipate and resolve issues before commissioning, ensuring efficient integration into the production line. Its ability to coordinate industrial robots with other manufacturing processes enhances precision, safety, and flexibility in automated operations.

Benefits of implementing DELMIA Robotics

Reduced commissioning times

Offline programming and prior simulation enable faster implementation of robotic systems, minimizing downtime.

Improved quality and precision

Process validation and optimization ensure more precise and consistent robotic operations, improving the quality of the final product.

Flexibility and adaptability

The ability to quickly reprogram and adjust robotic operations allows companies to adapt to changes in demand or product design.

Reduced operational costs

The optimization of paths and work cycles reduces energy consumption and equipment wear, lowering maintenance and operating costs.

Smart automation with DELMIA Robotics

By adopting DELMIA Robotics, companies can transform their manufacturing operations, achieving greater competitiveness and innovation capability in an ever-evolving industrial environment.

Discover how DELMIA Robotics solutions can optimize your robotic processes, improving efficiency, quality, and flexibility in your company. Contact us..

News and trends around DELMIA Robotics

ARITEX Group adopts 3DEXPERIENCE on the cloud to connect its international sites

With Dassault Systèmes’ 3DEXPERIENCE — including CATIA, DELMIA and SIMULIA — ARITEX Group connects its sites across Europe, the Americas and Asia in the cloud, improving collaboration and ensuring traceability throughout every project phase. With the migration from V5...

Robotics Virtual Commissioning: virtual validation of robots and automated systems

Integrating robots into complex production lines is not an easy task.A small synchronization error, poorly defined logic, or an unexpected movement can result in hours of downtime and thousands of euros in losses. In an environment where efficiency makes the...

Manufacturing blind: the day-to-day reality of many non-digitalized plants

The real impact of not connecting design, planning, and shop floor operationsMany manufacturing plants are still operating as they did decades ago: printed drawings, verbal work orders, constantly changing Excel sheets. And all of this leads to errors. Assembly...