In many industrial companies, CAD models contain the most valuable product information… yet they remain trapped inside engineering. The result is familiar: slow reviews, constant uncertainty between departments, dependence on CAD licenses, and errors that could have been prevented long before manufacturing.

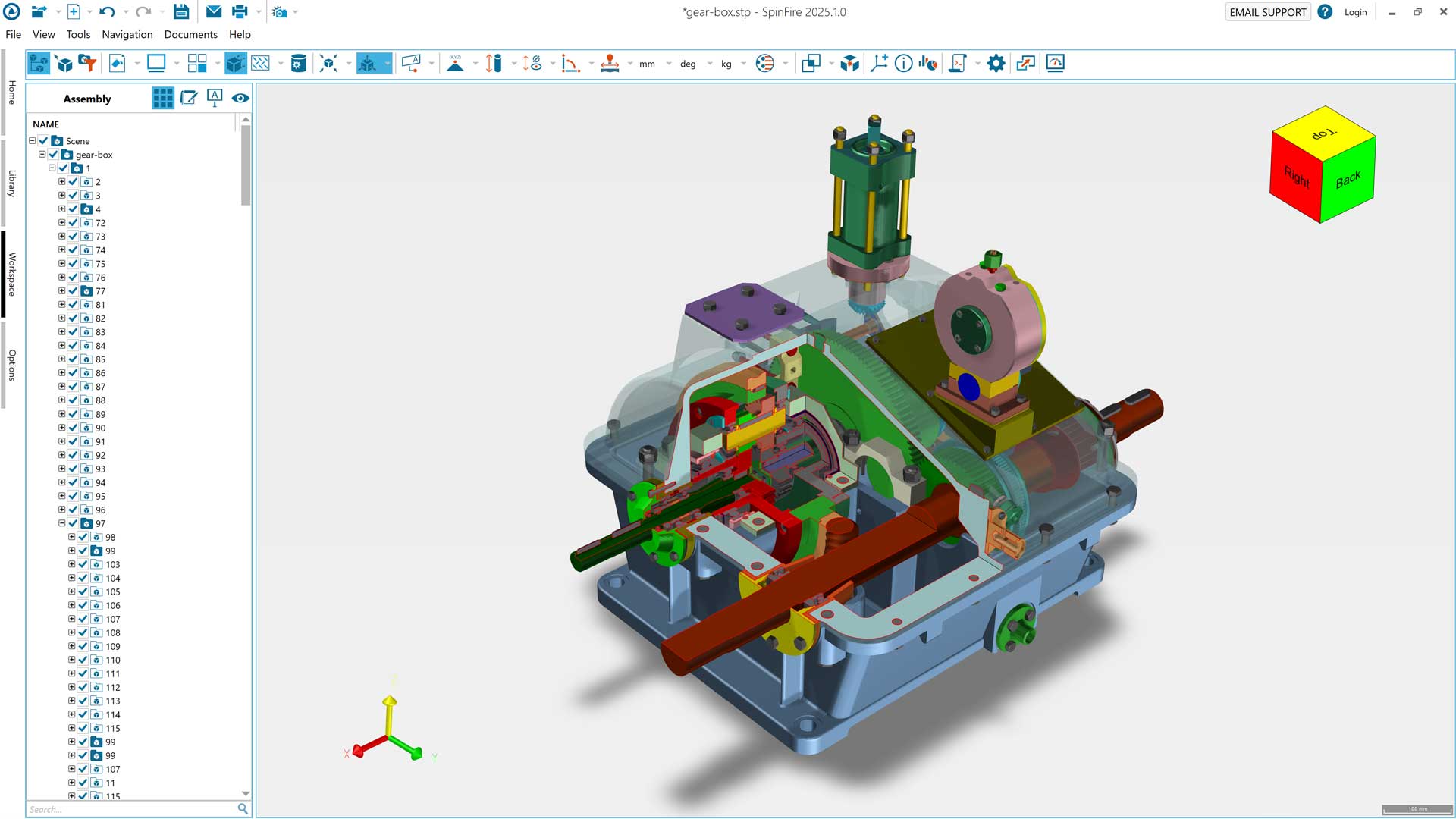

SpinFire Insight breaks that pattern. It’s not just a 3D viewer—it’s a way to make design understandable, accessible, and useful for the entire organization. These are the key reasons why.

1.Universal CAD visualization: open any model without friction

Industrial environments deal with multiple CAD formats: internal, customer, supplier, legacy… and not always with the same tool.

SpinFire allows opening and working with the main 3D/2D formats without needing the original CAD system. This removes common blockers such as:

- “I can’t open that file”

- “Send it to me in another format”

- “I need to ask engineering”

Information flows from the very first minute, with no conversions and no wasted time.

2. Precise measurement and analysis without touching the original CAD

Many daily decisions depend on a measurement, a section, or a volume. And often, to get that information, engineering is interrupted or an export must be requested.

With SpinFire, any authorized team can:

-

measure distances, angles, thicknesses, or radii,

-

generate sections,

-

calculate areas, volumes, or basic properties,

-

analyze geometry to validate fits or spaces.

All without modifying the model, preserving design integrity and avoiding risks.

3. Technical metadata accessible for quality, purchasing, and production

Modern CAD models are not just geometry. They include PMI, GD&T, 3D annotations, and manufacturing data.

SpinFire makes this information visible and accessible to those who need it outside engineering, for example:

-

Quality teams validating tolerances and requirements.

-

Production teams checking assembly or machining conditions.

-

Purchasing teams exploring alternatives with real design data.

This avoids subjective interpretations and improves decision traceability.

4. Model comparison to control changes and prevent errors

One of the biggest sources of error in industrial engineering is version management: parts changing without anyone noticing, assemblies not fitting because someone used an outdated file, small differences turning into major issues on the shop floor.

SpinFire includes tools to compare parts or assemblies and detect:

-

added/removed material,

-

key geometric changes,

-

differences between iterations.

This makes reviews faster and approvals more reliable.

Conclusion: CAD stops being a file and becomes a common language

SpinFire turns CAD models into a shared tool for the entire company: easy to open, easy to analyze, and safe for collaboration.

This leads to:

-

faster reviews,

-

fewer errors before manufacturing,

-

quicker decisions,

-

and an organization aligned around the same design.

When CAD is accessible, the product moves forward faster.

Do you want your teams to work on the same model without relying on CAD?

Contact CADTECH and discover how SpinFire can speed up your reviews and improve collaboration across your company.

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177