VAERIDION, a German aircraft manufacturer, is developing its 100% electric Microliner with a clear goal: to fly regional routes with zero emissions and achieve EASA CS-23 certification by 2030. To move at that pace on such a “non-conventional” program, the company has adopted the 3DEXPERIENCE platform as a central environment for design, simulation, and certification, relying on a virtual twin that connects engineering, manufacturing, and regulatory compliance end to end.

An electric aircraft for the new regional mobility

The Microliner is designed for nine passengers and two pilots and was created to fill a real market gap: short routes that are currently expensive or unfeasible with conventional aircraft. Its ambition is to open connectivity between European regions with poor road or rail alternatives, driving more flexible and accessible mobility.

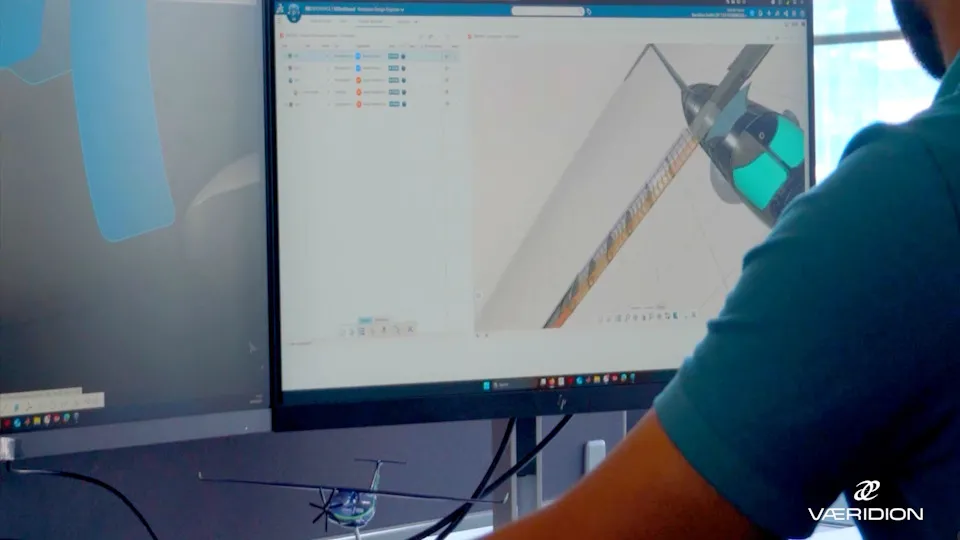

The technical key lies in its architecture: modular batteries integrated within the wing (“battery wing integration”). This decision enables a thin, high-aspect-ratio wing without structural penalties, maximizing aerodynamic efficiency and energy capacity without significantly increasing fuselage weight. This is complemented by a multi-motor electric propulsion system with a single propeller, providing redundancy and safety with centered thrust. The result: zero CO₂ and NOx emissions, no contrails, and lower noise levels than a traditional turboprop.

The challenge: an “out-of-the-ordinary” design that must be certifiable

Developing a fully electric aircraft requires solving challenges that are uncommon in classical aeronautics: optimizing performance across all phases of flight (short-runway takeoffs, efficient cruise, maximum range) while reducing every kilogram of structure to accommodate more energy. And all of this with an additional requirement: certifiability from day one, in an industry where every change must be traceable and demonstrable to regulators.

The solution: a complete stack on a single platform

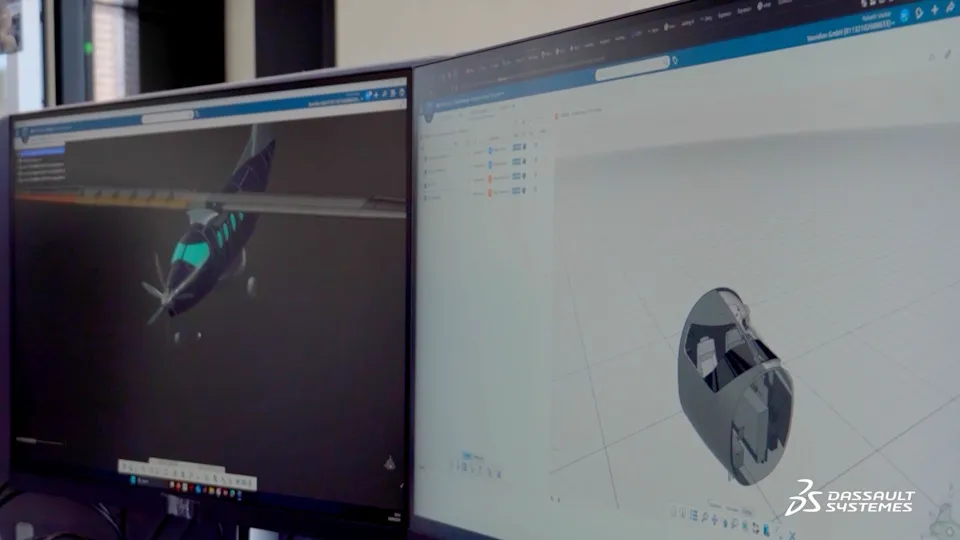

VAERIDION has brought together all the program’s critical tools within 3DEXPERIENCE:

- CATIA for mechanical design, from concept to detail.

- SIMULIA for automated simulations that reduce manual tasks and speed up iterations.

- ENOVIA for project coordination, requirements management, and cloud-based data with a single source of truth.

The advantage is not only technological, but operational: avoiding friction between multiple tools and ensuring the entire organization works with the same data, in real time.

“With 3DEXPERIENCE we have all the essential tools on a single platform. It reduces inefficiencies and ensures data accuracy,” explains Markus Kochs-Kämper, CTO of VAERIDION, who describes the environment as a “Swiss Army knife” due to its flexibility.

Virtual twin to optimize batteries… and carry data into production

The virtual twin has been instrumental in testing battery configurations, optimizing installation and maintenance, and detecting issues before manufacturing. The virtual twin acts as a “master of data”: it centralizes 3D design and configuration and extends into the shop floor during battery module manufacturing. This ensures true digital continuity between engineering and production, reducing uncertainty when the physical prototype is launched.

EASA certification: end-to-end traceability

VAERIDION began its relationship with EASA early and completed its Pre-Application Contract, paving the way for certification-compliant prototype flights in 2027 and the CS-23 target in 2030. The platform enables end-to-end process documentation: certification basis, requirements, decisions, changes, and evidence of compliance with full traceability and a single source of truth.

About VAERIDION

Based in Munich and with an international team of over 70 experts, VAERIDION is developing a regional eCTOL with a range of up to 400 km, inspired by glider wings and electric propulsion with integrated batteries. Its commitment to 3DEXPERIENCE and the virtual twin aims to accelerate the arrival of electric, quiet, and commercially viable regional aviation before 2030.

More information: https://vaeridion.com/

Read the full case study on the Dassault Systèmes website here.

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177