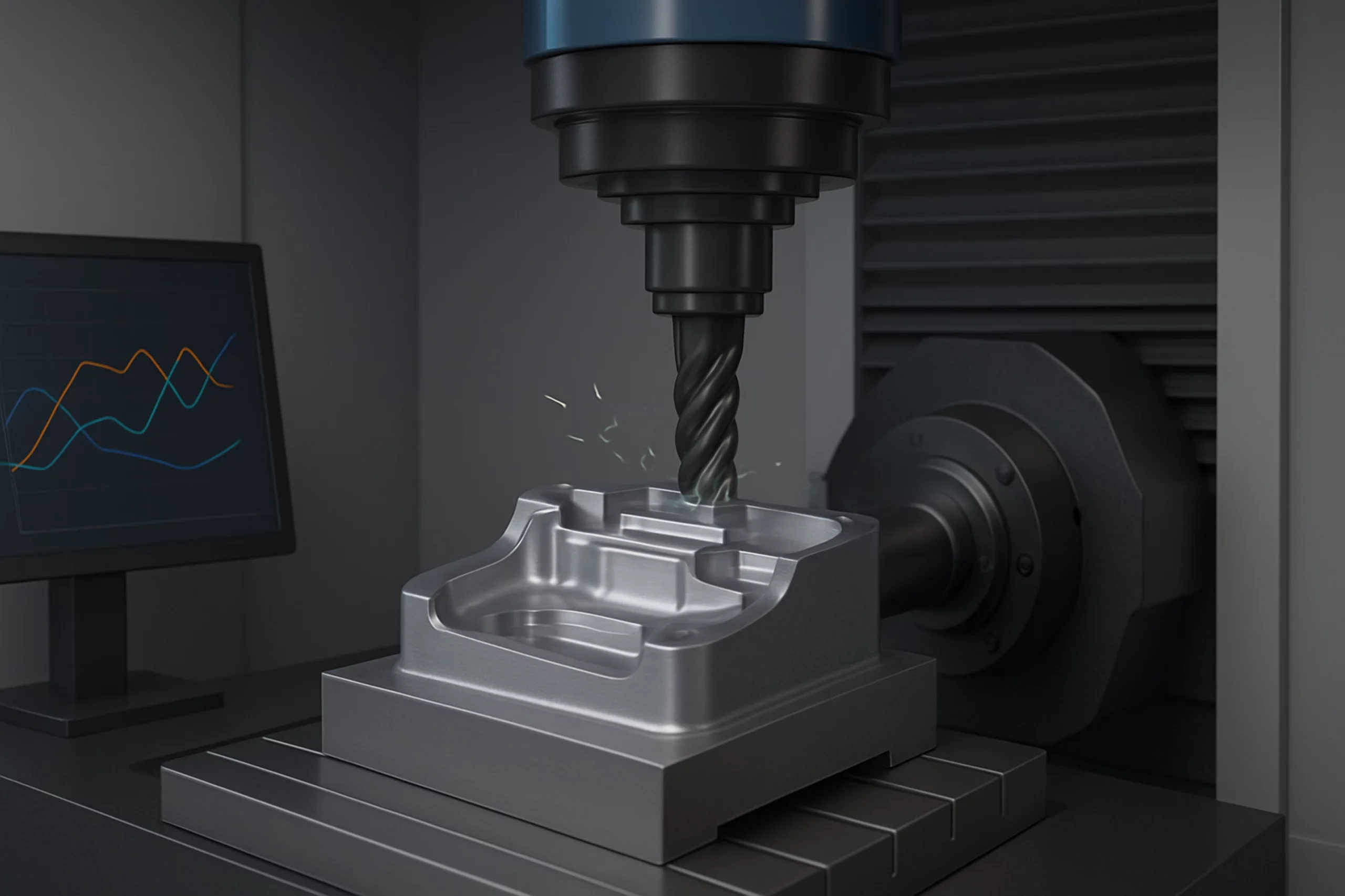

In CNC machining, every minute counts. Deadlines are tighter, pressure to reduce costs is increasing, and quality requirements leave no room for error. In this context, reducing cycle times without compromising quality or safety has become one of the industry’s major challenges.

The problem: programs that fail to realize their full potential

Although CAM systems generate correct toolpaths, the resulting NC programs do not always fully take advantage of real cutting conditions.

In many cases, feed rates are conservative, cutting forces are unbalanced, or overloads occur in certain areas of the part.

The result: longer machining times than necessary, premature tool wear, and higher energy consumption than expected.

The solution: autonomous optimization with real data

VERICUT Optimizer analyzes the NC program from a physical perspective: cutting forces, chip load, tool deflection, and material removal rates.

Using this information, it automatically adjusts feed and cutting parameters to achieve the perfect balance between speed, safety, and quality.

Best of all, it integrates easily into any existing workflow, optimizing already-generated programs without the need to rebuild them from scratch.

The benefits of optimizing intelligently

Adopting autonomous optimization with VERICUT Optimizer delivers immediate and measurable results:

- Cycle time reductions of up to 25% or more in many cases.

- Longer tool life, thanks to a balanced distribution of cutting forces.

- Energy savings by avoiding inefficient cuts or unnecessary overloads.

- Greater process stability, with parts machined consistently and without risk.

In short, optimizing is not about redoing, it’s about improving what already exists. And that continuous improvement is the key to gaining minutes on every part, transforming shop productivity, and protecting the investment in equipment and tools.

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177