In CNC machining, the pressure to increase productivity often leads to using increasingly aggressive cutting parameters. In the short term it may seem like a solution, but the result is often the opposite: accelerated tool wear, higher risk of breakage, and unstable processes that affect part quality.

True efficiency is not about pushing resources harder, but about using them more intelligently.

The problem: cutting conditions that shorten tool life

When parameters are not balanced, cutting forces exceed the tool’s limits. This causes vibrations, deflection, and premature wear that forces production to stop for tool changes.

Beyond replacement costs, each stoppage means lost time and a direct impact on profitability.

The solution: adjust intelligently, not excessively

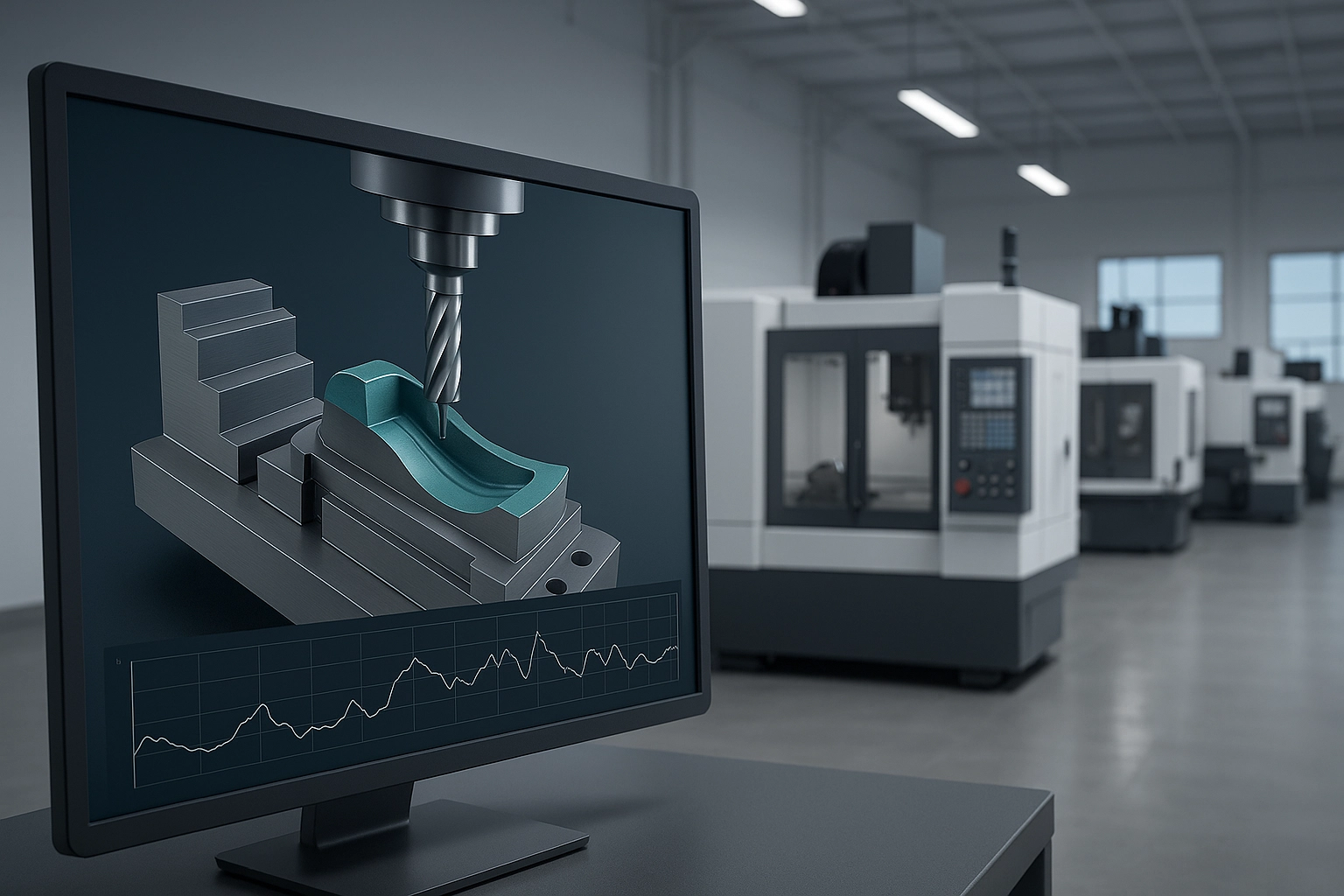

With VERICUT and VERICUT Optimizer, NC programs are analyzed from a physical perspective: chip load, cutting forces, deflection, and material removal rates.

Based on this data, the software automatically adjusts feed and cutting parameters to keep the process under control.

The result is a tool that always operates under optimal conditions, without being underutilized or pushed to its limits.

The benefits of more sustainable machining

Optimizing does not mean slowing down productivity—quite the opposite. The advantages of a more balanced process are evident from day one:

- Fewer tool changes, enabling more continuous processes.

- Greater machining stability, avoiding vibrations and deviations.

- Cost and time savings by reducing wear and unexpected downtime.

- Sustainability, by making better use of resources and reducing energy consumption.

In short, machining smarter, not harder means extracting maximum performance while taking care of every resource. And in machining, the cutting tool is one of the most valuable.

Do you want to extend the life of your tools and gain real productivity?

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177