Marcopolo, one of the world’s largest bus manufacturers, has adopted the 3DEXPERIENCE platform to master the complexity of its engineering and bring customization to a global scale. With more than 750 engineers and industrial operations on five continents, the Brazilian company needed a single environment to manage millions of parts and coordinate multidisciplinary teams. The results are compelling: four times faster development, 30% fewer engineering errors, and buses reaching the market one year earlier.

Mass customization with millions of parts

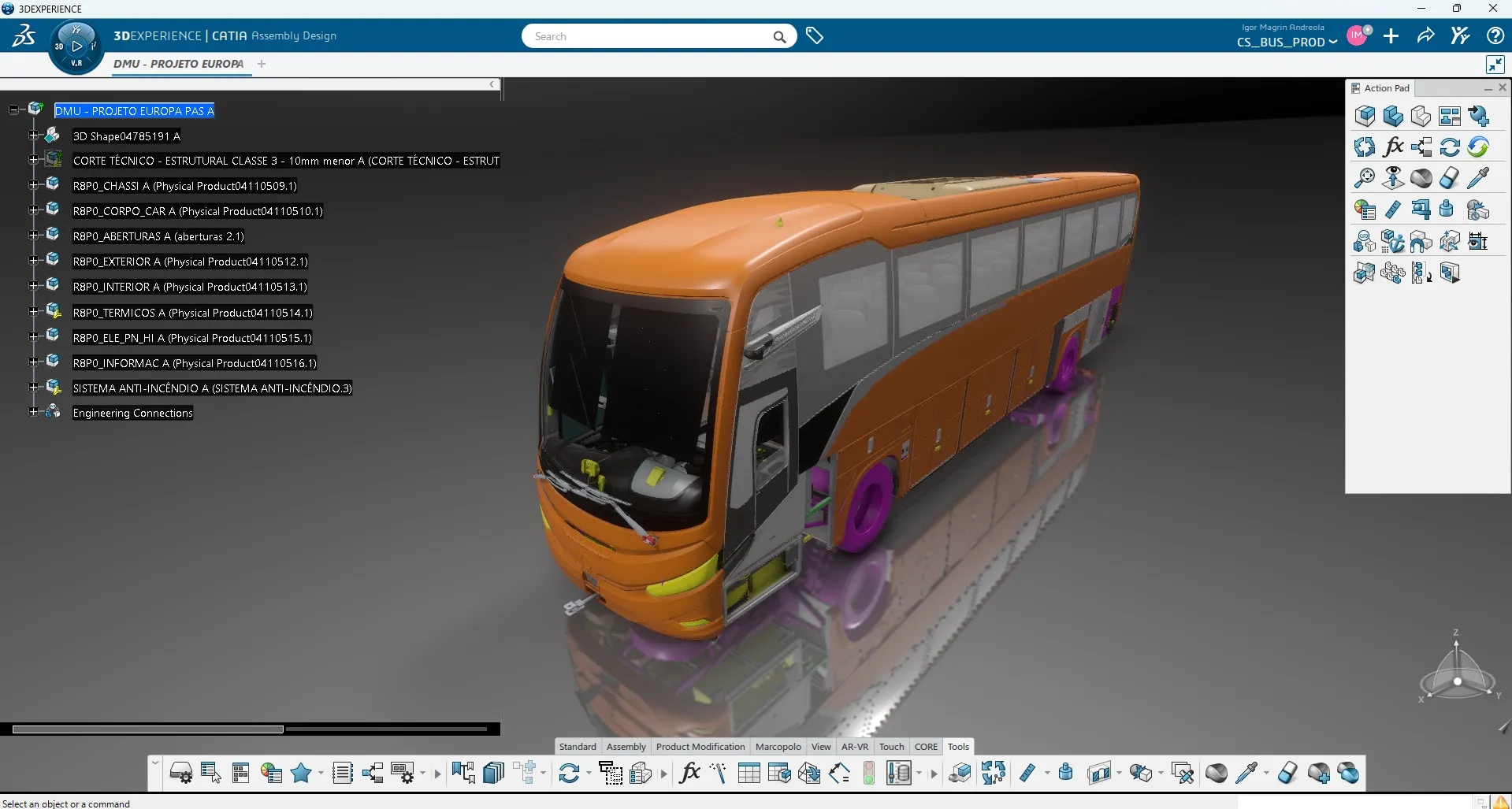

From its headquarters in Caxias do Sul, Marcopolo designs customized transport solutions: hybrid and electric buses, trains, trams, and motorhomes manufactured in 11 plants and distributed to more than 140 countries. A single double-decker bus can integrate 5,000 components, and the company manages a repository of more than two million unique parts, creating around 600 new ones every day. Maintaining technical consistency, costs, and regulatory compliance across such diverse markets required a major step forward in integration.

The challenge: design silos and late validation

Before 3DEXPERIENCE, teams worked with separate tools: one group designed the bodywork, another the moving parts, and another the electrical system. This way of working led to two critical problems. First, system-level validation only took place at the physical prototype stage; it could take months to discover incompatibilities between parts, generating rework and cost.

Second, the data flow was fragile: although the design was synchronized with the ERP, entry into the PLM was manual. The situation worsened when Marcopolo learned that future ERP versions would no longer be compatible with its design software.

The solution: a modern, ERP-compatible environment

With more than 30 years of using Dassault Systèmes technology (SOLIDWORKS, CATIA V5), the transition to 3DEXPERIENCE—with CATIA for design and ENOVIA for data management—was a natural decision. The platform made it possible to centralize all technical information in a single source, compatible with the current ERP and ready for future versions.

Adoption was supported by a cultural change program with the help of Dassault Systèmes and its local partner SKA: first aligning people, then providing specific training for bus development, and establishing a clear rule—new designs would be created in CATIA.

Impact: real-time collaboration and virtual validation

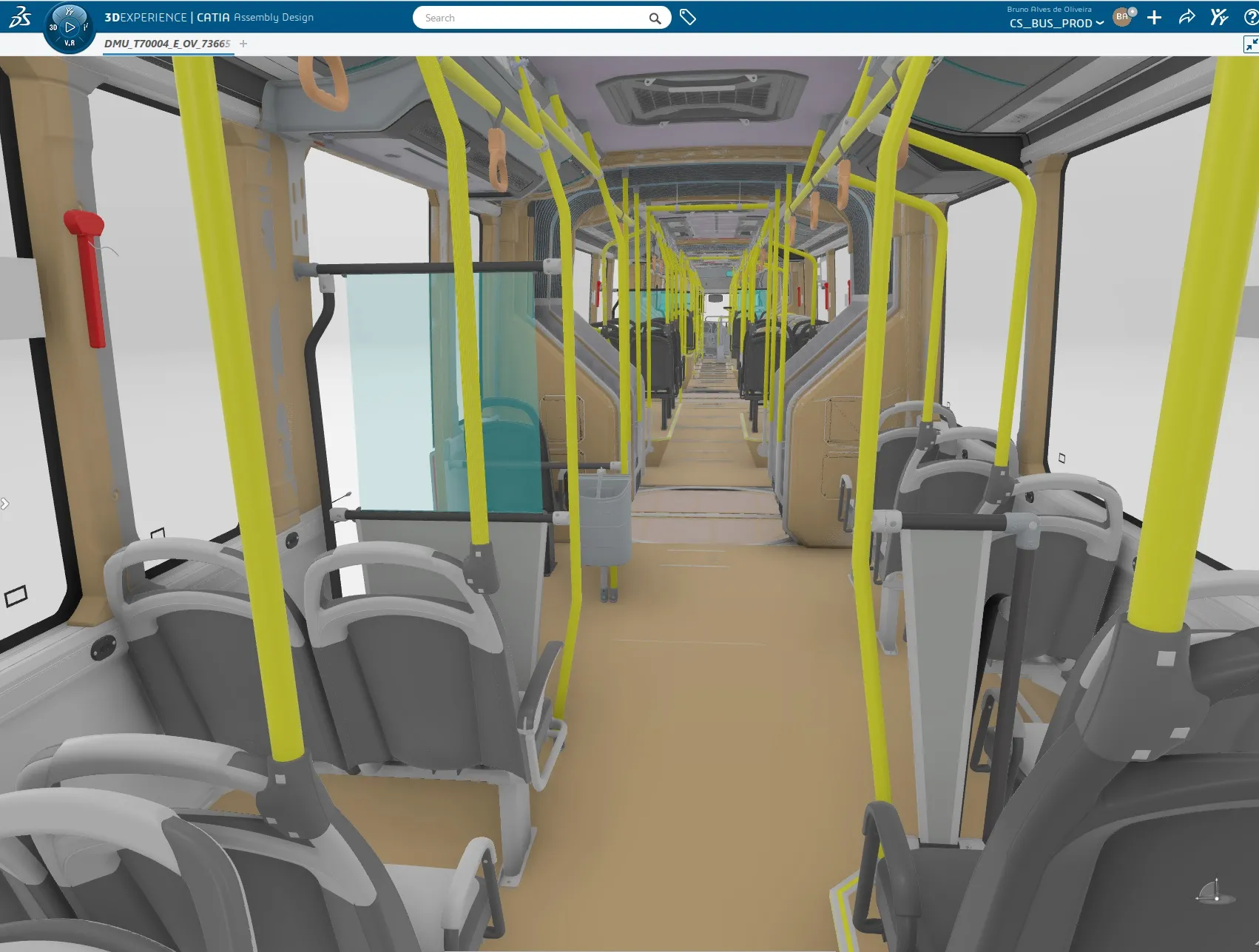

The shift to a single environment changed the way design is done. CATIA enables work with complete assemblies, allowing each engineer to design their part within the context of the vehicle. ENOVIA acts as a “single source of truth,” enabling real-time collaboration on the latest version. This has made it possible to move from managing one or two large projects simultaneously to running several in parallel, with teams of up to 70 people on a single project.

Validation was also brought forward: with the Digital Mockup (DMU), teams review and validate the bus digitally before building a physical prototype. If a part is modified, the 3D twin is automatically updated, preventing inconsistencies across disciplines. Virtual reality headsets are even used to walk through the model and detect issues from the very beginning.

Measurable results

- Four times faster development thanks to centralized data.

- 30% fewer engineering errors through DMU validation.

- 50% less time spent on prototype production.

- Generation 8 reached the market one year earlier than previous models.

“The Generation 8 buses, developed entirely on 3DEXPERIENCE, reached the market one year earlier. Twenty-two years ago, this would have been unthinkable,” highlights Tiago Mendes da Silva, engineering coordinator.

Beyond engineering: plant digitalization and configurator

Marcopolo is already extending 3DEXPERIENCE to its plants, with operators accessing information via tablets and screens on the assembly line. Soon, it will incorporate DELMIA to program and optimize 80 robots and simulate work cells. In addition, the platform powers an online configurator capable of managing up to two million combinations, simplifying the purchasing process for customers and further accelerating development.

About Marcopolo

Founded in 1949, Marcopolo is among the world’s largest bus manufacturers. The company is committed to the future of mobility and closely follows the development of new sustainable transportation modes. It continuously invests in improvement, technology, design, and expansion, producing solutions that contribute to the development of collective passenger transport. With plants on five continents, the company’s vehicles can be found on the roads of more than one hundred countries.

More information: www.marcopolo.com.br/en

Read the full case study on the Dassault Systèmes website here.

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177