Modern mechanical engineering demands more than a powerful 3D modeler. Teams need the freedom to design, validate earlier, collaborate more effectively, and make decisions based on reliable data — all without extending timelines or increasing costs.

CATIA 3DEXPERIENCE addresses these challenges by combining design, simulation, and collaboration on a single platform. These are the 10 key advantages that explain why it has become an industry benchmark.

1. Unlimited modeling without compromise

Engineers should never have to adapt their designs to software limitations. The digital model must accurately represent physical reality to avoid late changes, rework, and unnecessary physical prototypes.

CATIA stands out for its robustness and geometric precision, allowing engineers to iterate with confidence even on highly complex models. This reliability is essential in industries such as aerospace, automotive, and industrial equipment, where model accuracy directly impacts cost, timelines, and quality.

2. Advanced surfacing for functional and aesthetic design

Surfaces do more than define shape — they influence aerodynamics, energy efficiency, and product perception.

CATIA combines high-precision solid modeling with advanced Class A surfacing capabilities, enabling the creation of complex, continuous, and visually flawless geometries. This combination is especially valuable in industries where design and performance go hand in hand.

3. Fast learning curve and intuitive user experience

An engineer’s time should be spent designing, not fighting complex interfaces.

The 3DEXPERIENCE CATIA user experience is built around contextual menus, consistent logic, and optimized workflows, enabling fast adoption for both new and experienced users. All applications follow the same interaction principles, making it easy to access advanced functionality without friction.

4. Real productivity through automation

Repetitive tasks consume time and increase the risk of errors.

CATIA includes features that automate common operations, such as fillets, draft angles, and design rules. It also allows companies to capture internal know-how through rules and parameters, ensuring consistency and accelerating development cycles without relying on manual processes.

5. Geometry reuse and Multi-CAD compatibility

Recreating existing work is inefficient and risky.

3DEXPERIENCE CATIA enables the editing and reuse of geometry from multiple CAD systems, including legacy data and supplier models. Its surface repair capabilities ensure imported geometry is reliable and ready for use from day one.

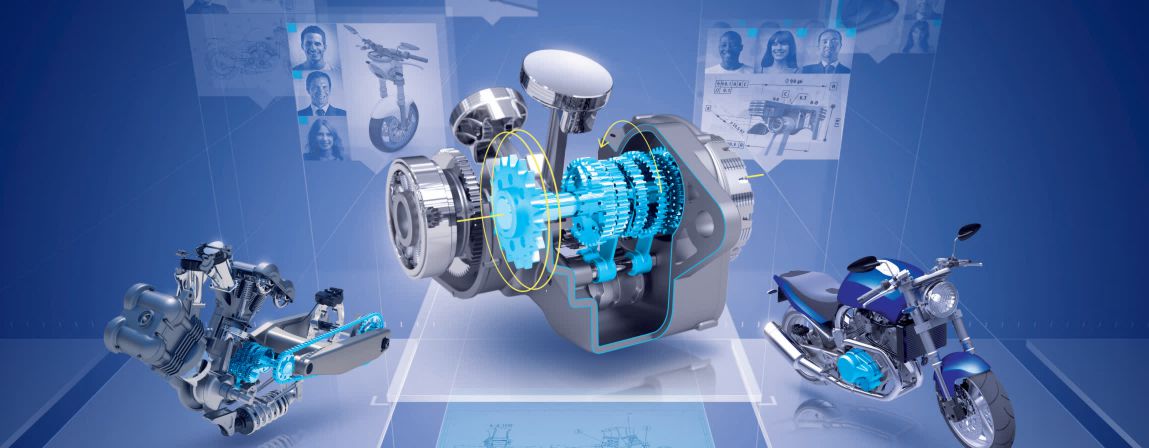

6. Smooth handling of complex assemblies

In projects involving large assemblies, performance and collaboration are critical.

CATIA is designed to manage large-scale assemblies with speed and stability, even those containing hundreds of thousands of components. Engineers can isolate specific areas, work in context, and maintain a global view of the product without compromising performance.

7. Concurrent engineering and real-time collaboration

Lack of coordination leads to errors, delays, and redesigns.

With 3DEXPERIENCE CATIA, teams can work concurrently, visualizing in real time the changes that impact their work. This enables earlier interference detection, faster reactions, and prevents conflicts that would otherwise surface too late in the development cycle.

8. Design and simulation on a single model

Identifying issues as early as possible makes a major difference in cost and time.

CATIA allows engineers to design and simulate on the same model, eliminating conversions, exports, and inconsistent versions. This accelerates validation, improves decision-making, and enables seamless collaboration between designers and analysts from the earliest stages of development.

9. Design for manufacturing from the start

Just because something can be designed does not mean it can be manufactured efficiently.

CATIA provides tools that help engineers make design decisions aligned with manufacturing realities, regardless of material or process: machining, injection molding, stamping, welding, or additive manufacturing. Design changes are automatically reflected in manufacturing data, improving alignment between engineering and production.

10. Secure collaboration across people, processes, and data

Product development involves multiple internal and external teams.

3DEXPERIENCE CATIA enables collaboration through controlled access to the model on the platform, eliminating file transfers and loss of control over versions or intellectual property. Each user accesses only the information they need, with full traceability and security.

Conclusion: a solid foundation for more efficient engineering

Choosing the right design tool has a direct impact on productivity and profitability. Thanks to its capabilities in design, simulation, assembly management, and collaboration, CATIA 3DEXPERIENCE helps significantly improve engineering efficiency and reduce errors in critical development phases.

In addition, its flexible deployment options — public cloud, private cloud, or on-premise — make adoption frictionless, allowing companies to start generating value from day one.

Designing better is not just an option — it’s a competitive advantage

At CADTECH, as a Platinum Partner of Dassault Systèmes, industrial companies are supported in getting the most out of CATIA 3DEXPERIENCE, tailoring it to their real processes and business needs.

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177