The pressure to manufacture lighter, stronger, and more sustainable products is transforming industries such as automotive, aerospace, energy, and sports. The key lies not only in design, but also in the materials used.

Composites and advanced materials are the answer to this need. However, working with them presents unique challenges: fiber orientation, anisotropic behavior, layup processes, and production costs. These are aspects that cannot be addressed with conventional design tools.

This is where Dassault Systèmes’ CATIA 3DEXPERIENCE makes the difference, by providing an integrated environment for the design, simulation, and manufacturing of composite material structures.

The challenge of advanced materials

Composites do not behave like traditional metals or plastics. Their properties depend on how fibers and resins are combined, the direction of the filaments, and the manufacturing process used.

The main challenges for companies are:

- Accurately modeling material characteristics.

- Optimizing fiber orientation to maximize strength and minimize weight.

- Ensuring design manufacturability while accounting for layup and curing constraints.

- Reducing costs and waste in high-value materials.

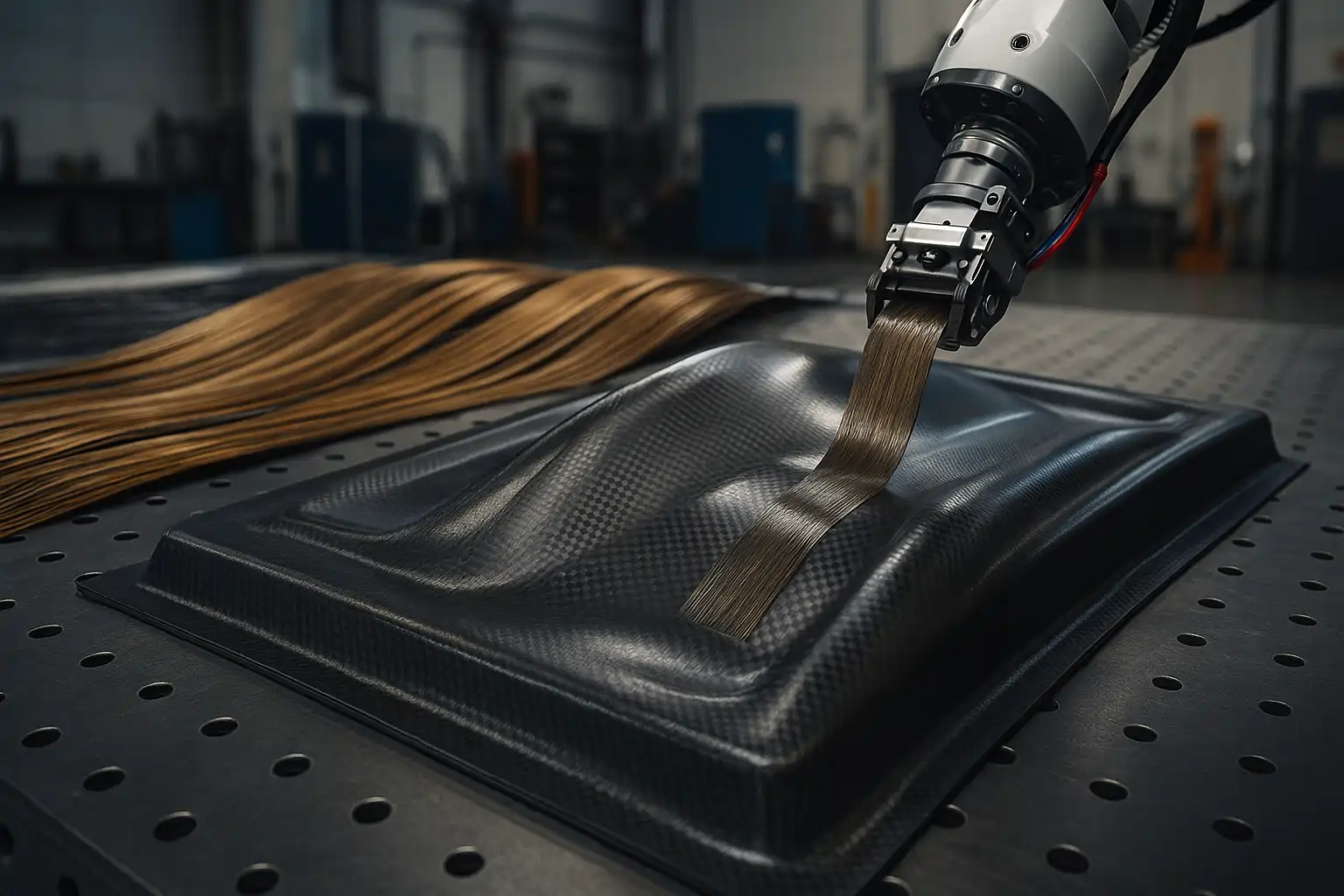

How CATIA helps master composites

CATIA offers a set of dedicated capabilities that make it possible to tackle these challenges in an integrated way:

- Advanced composite modeling: definition of plies, fiber angles, and layup sequences.

- Structural optimization: simulation of stresses and deformations to refine the design before manufacturing.

- Manufacturing process integration: verification of draping behavior and compatibility with production processes.

- Cloud-based collaborative management: all teams — design, simulation, and manufacturing — work on the same up-to-date information.

The result: lighter, stronger products with a lower risk of errors on the shop floor.

Impact on sustainability and competitiveness

Adopting composites and advanced materials not only improves the technical performance of products, but also delivers strategic benefits:

- Lower carbon footprint, thanks to lighter parts that reduce energy consumption during transport and operation.

- Greater mobility efficiency, with vehicles that consume less fuel or battery power.

- Increased range in aerospace, by reducing the structural weight of aircraft.

- Differentiating innovation, with materials that enable designs impossible to achieve with conventional metals.

Tangible benefits for industry

- Weight reduction and increased energy efficiency.

- Less material waste in manufacturing processes.

- Greater reliability and structural strength.

- Shorter development cycles thanks to integration between design and manufacturing.

Conclusion

Engineering no longer depends only on new ways of designing, but also on the materials used to manufacture products.

CATIA enables companies to fully leverage the potential of composites and advanced materials by combining design, simulation, and manufacturing in a single integrated environment.

In an increasingly demanding market, innovation is measured in grams saved, emissions reduced, and products that truly make a difference.

Would you like to reduce errors and costs when working with composites and advanced materials?

comunicacion@cadtech.es – 800 007 177