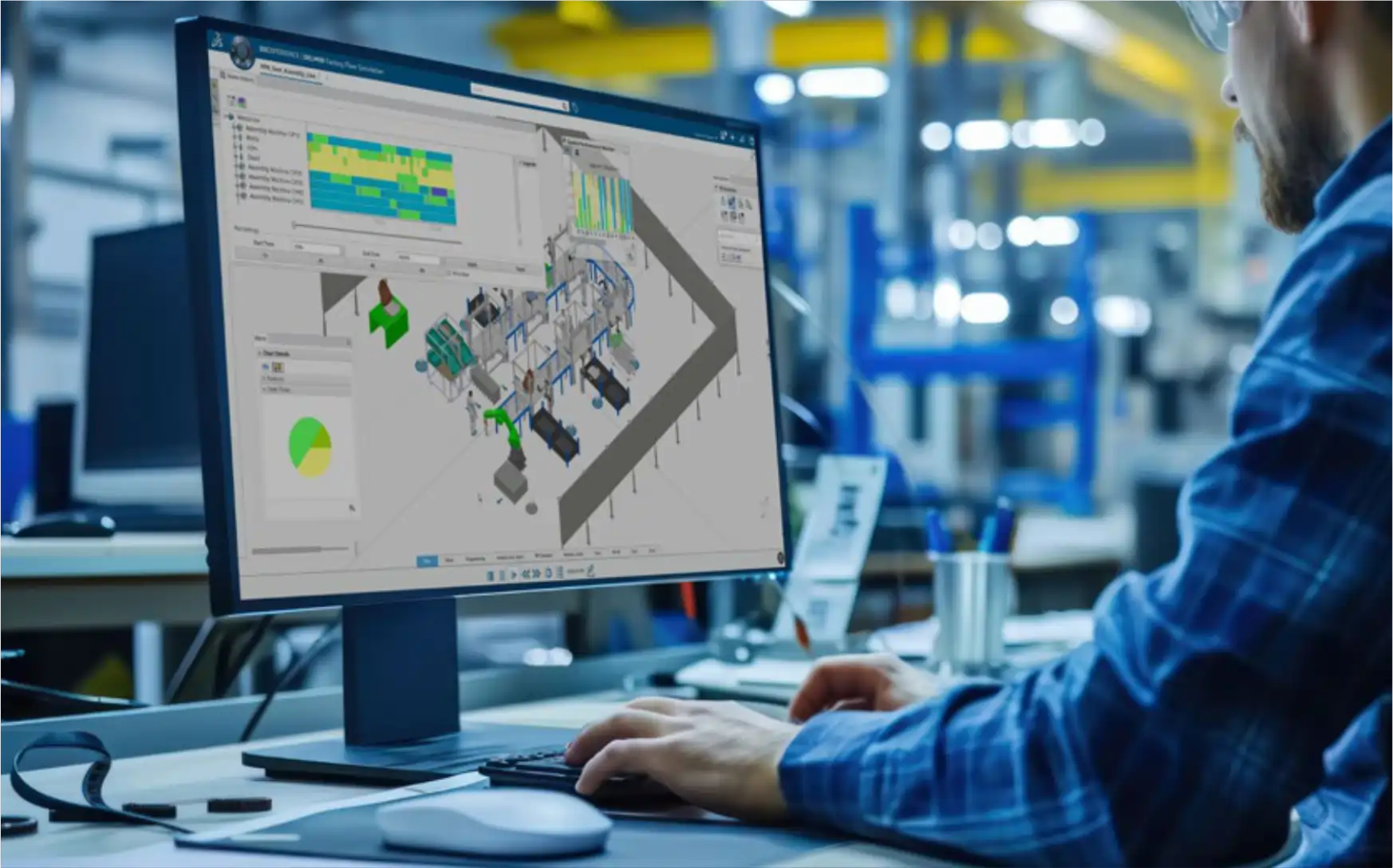

DELMIA Plan Simulation, part of Dassault Systèmes’ 3DEXPERIENCE platform, provides advanced tools for manufacturing process planning and simulation. Its modeling capabilities allow issues to be anticipated and corrected before production, ensuring more efficient and cost-effective operations.

DELMIA Plan Simulation

Optimization of manufacturing process planning and simulation

Through detailed workflow simulation, DELMIA Plan Simulation helps optimize resource allocation, minimize downtime, and improve quality at every stage of the production process. Its integration with other manufacturing systems enables agile planning and data-driven decision-making in real time.

Key areas of DELMIA Plan Simulation

Manufacturing process simulation

Shop floor workflow simulation: allows modeling and analysis of production line layouts, identification of bottlenecks, and improvement of operational efficiency.

Production performance optimization: helps evaluate the impact of process changes, maximizing resource utilization and reducing downtime.

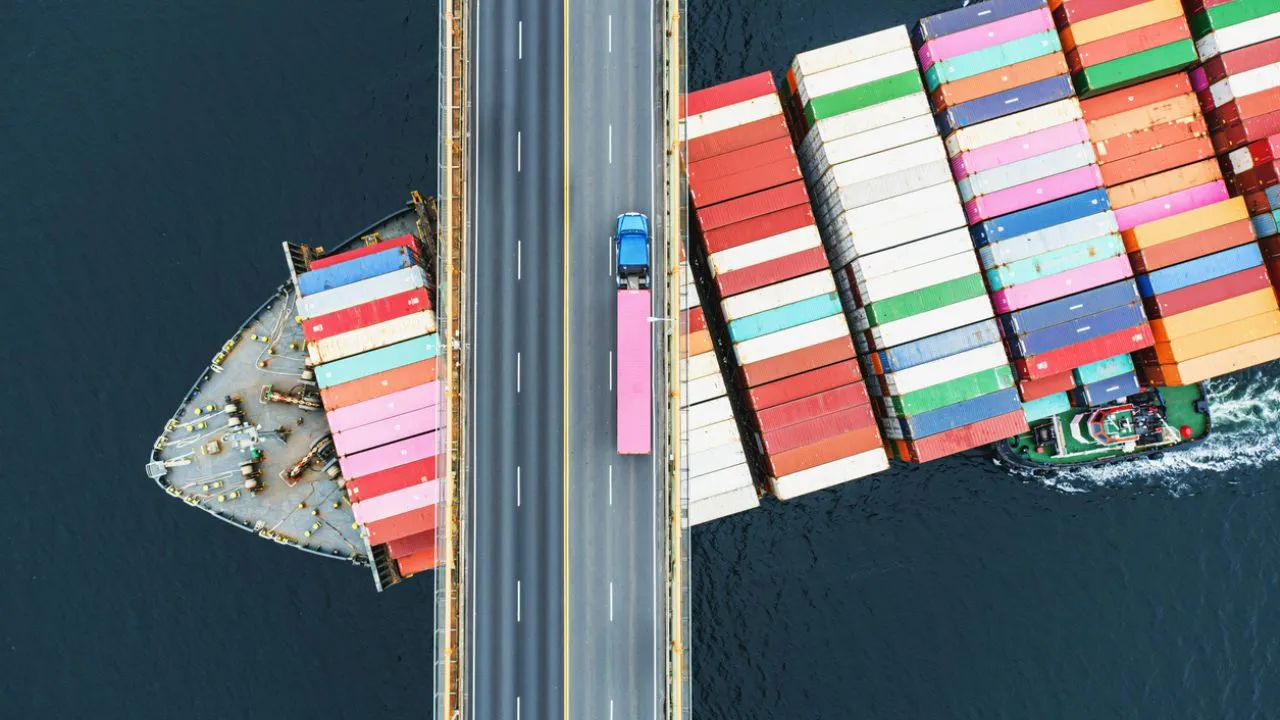

Logistics and material flow simulation

Material flow simulation: optimizes inventory management and material supply at each stage of production, ensuring efficient logistics.

Modeling and optimization of internal transport: allows simulation of material and product movement within the plant, ensuring smooth and efficient distribution.

Production scenario evaluation

Production scenario evaluation: allows simulation of different production and demand strategies, supporting data-driven decision-making.

Capacity and resource optimization: models the allocation of machines, operators, and production lines to maximize efficiency without wasting resources.

Benefits of implementing DELMIA Plan Simulation

Improved operational efficiency

By simulating and optimizing processes, companies can identify and eliminate inefficiencies, reducing cycle times and operating costs.

Increased product quality

Simulation allows potential defects in manufacturing processes to be anticipated and corrected, ensuring high-quality products.

Reduced workplace risks

Ergonomic evaluation and human task simulation help design safer work environments, reducing the risk of injuries and improving employee well-being.

Optimization of internal logistics

Simulation of material flows and internal transport systems enables more efficient supply chain management, reducing inventories and delivery times.

DELMIA Plant Simulation: intelligent planning for industry

By adopting DELMIA Plan Simulation, companies can transform their manufacturing processes, achieving greater competitiveness and adaptability in an ever-evolving market.

Discover how DELMIA Plan Simulation solutions can optimize your manufacturing processes, improving efficiency, quality, and safety in your company. Contact us.

News and trends around DELMIA Plant Simulation

Robotics Virtual Commissioning: virtual validation of robots and automated systems

Integrating robots into complex production lines is not an easy task.A small synchronization error, poorly defined logic, or an unexpected movement can result in hours of downtime and thousands of euros in losses. In an environment where efficiency makes the...

Virtual Commissioning: The Standard in Industrial Equipment Manufacturing

For years, commissioning has been the most unpredictable—and costly—phase of any industrial project.Endless hours of debugging, last-minute fixes, and improvised tests on the shop floor have turned this stage into a major production bottleneck.Every issue detected too...

Manufacturing blind: the day-to-day reality of many non-digitalized plants

The real impact of not connecting design, planning, and shop floor operationsMany manufacturing plants are still operating as they did decades ago: printed drawings, verbal work orders, constantly changing Excel sheets. And all of this leads to errors. Assembly...