GEMS Engineering, a Hungarian research and development company specializing in fusion technology, has taken a key step for its participation in ITER: deploying the 3DEXPERIENCE platform in the cloud. The goal was clear: to work in the same environment as Hungary’s Energy Research Centre (EK) and the rest of the ecosystem partners, eliminating collaboration friction and gaining speed. The result: a 15% increase in efficiency in the management and development of its systems.

Critical diagnostics for the energy of the future

ITER is the largest international experiment aimed at demonstrating that fusion can become a clean and viable energy source on a large scale. In this project, every advance depends on extreme coordination among multiple stakeholders. GEMS is fully focused on this mission, developing essential diagnostic systems for the tokamak. Among them stands out its erosion–deposition monitor, a device that allows remote observation of the reactor’s internal wear and anticipation of effects that could compromise its operation.

The decision: a single common environment

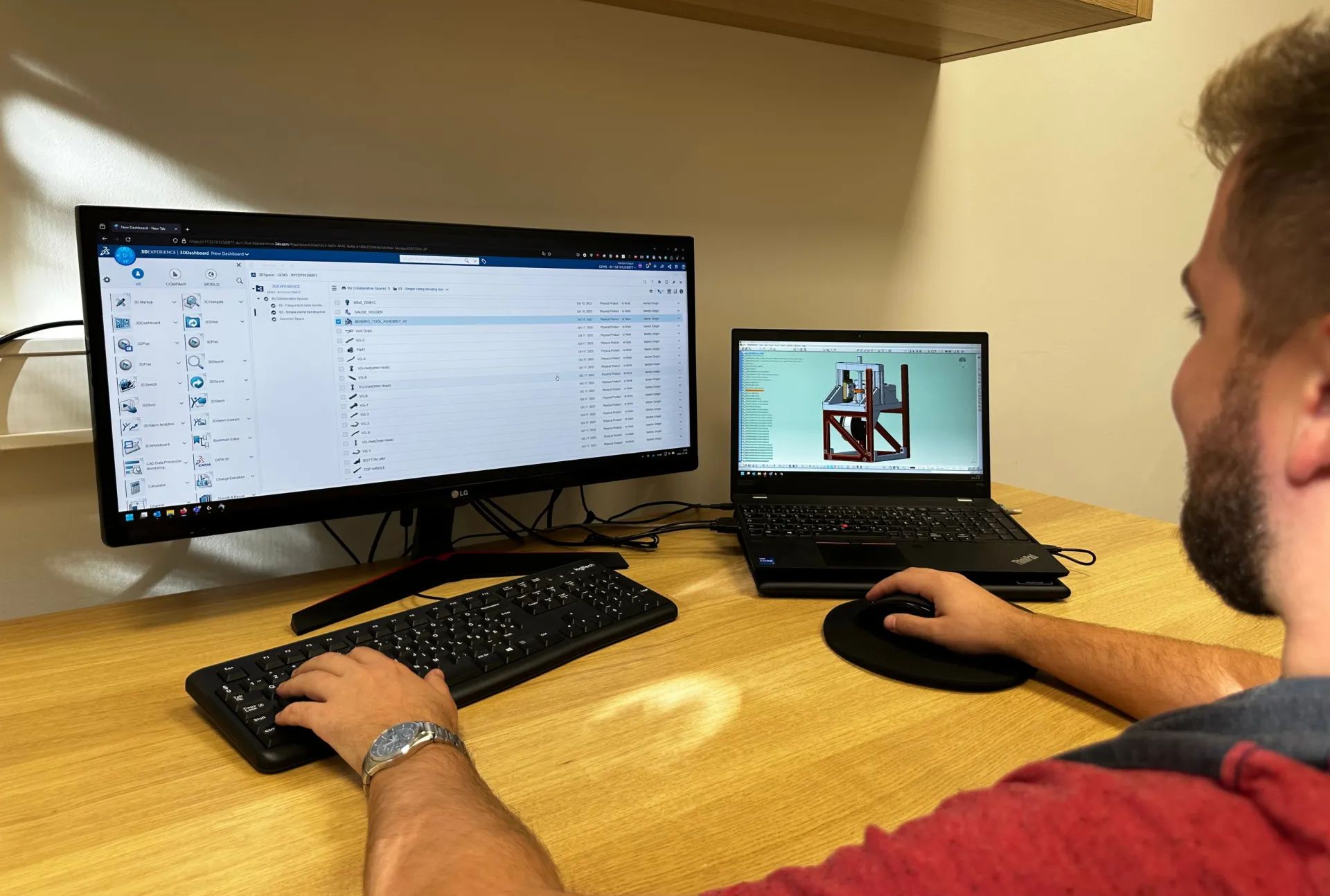

GEMS understood that adopting 3DEXPERIENCE Cloud was the next logical step. The local partner Cadterv played a key role in the deployment, showing how to unify users and data from GEMS, EK, and other stakeholders on a single platform. In addition, the POWER’BY functionality made it possible to migrate and reuse CATIA V5 files without redoing work, protecting previous investments. As a cloud environment, the implementation avoided lengthy internal processes and provided immediate access to the tools, reinforced with ongoing training and consulting.

Impact: greater efficiency, less noise

The platform has changed the way teams work. The company reports a 15% improvement in efficiency, thanks to more systematic data and project management. GEMS and EK engineers share information within the same environment in real time, replacing emails and external channels. The ability for concurrent design enables parallel progress from ideation to installation, with all experts working on a single source of truth. And the cloud model adds operational flexibility: access from any device and location, whether in the office or on the move.

“Thanks to the 3DEXPERIENCE platform, we have strengthened our position in a competitive market. We now collaborate better with key partners and compete with larger players in the energy sector,” says Gábor Veres, CEO of GEMS Engineering.

Next stop: virtual twin simulation

The adoption of 3DEXPERIENCE is just the beginning. GEMS plans to expand the environment with SIMULIA capabilities to validate the performance of its systems on the virtual twin before manufacturing physical prototypes. The goal: accelerate iterations, reduce risk, and continue gaining ground in strategic clean energy projects.

About GEMS Engineering

GEMS Engineering provides engineering and management solutions for knowledge-intensive projects, covering the entire development cycle — from concept to final installation — with a focus on fusion technology and advanced diagnostic systems.

More information: https://gems-engineering.com/

Read the full case study on the Dassault Systèmes website here.

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177