In CNC machining, every error comes at a high cost. A simple tool collision, an incorrect toolpath, or a poorly adjusted calculation can result not only in material waste, but also in machine damage, production delays, and unexpected costs that directly impact shop profitability.

Traditionally, many of these issues were detected on the machine itself during NC program prove-outs. But this approach involves lost time, resource consumption, and unnecessary risk. Today, companies looking to remain competitive can no longer afford such margins for error.

The challenge: from design to machining without blind spots

NC programs that appear correct in CAM software can hide errors that are difficult to identify at first glance. Factors such as the machine’s real behavior, cutting conditions, or potential collisions with fixtures and components of the machining center itself often emerge too late—right when the part is already in process.

In industries such as aerospace, automotive, or medical, where each part has high added value and deadlines are critical, the need to eliminate blind spots is more urgent than ever.

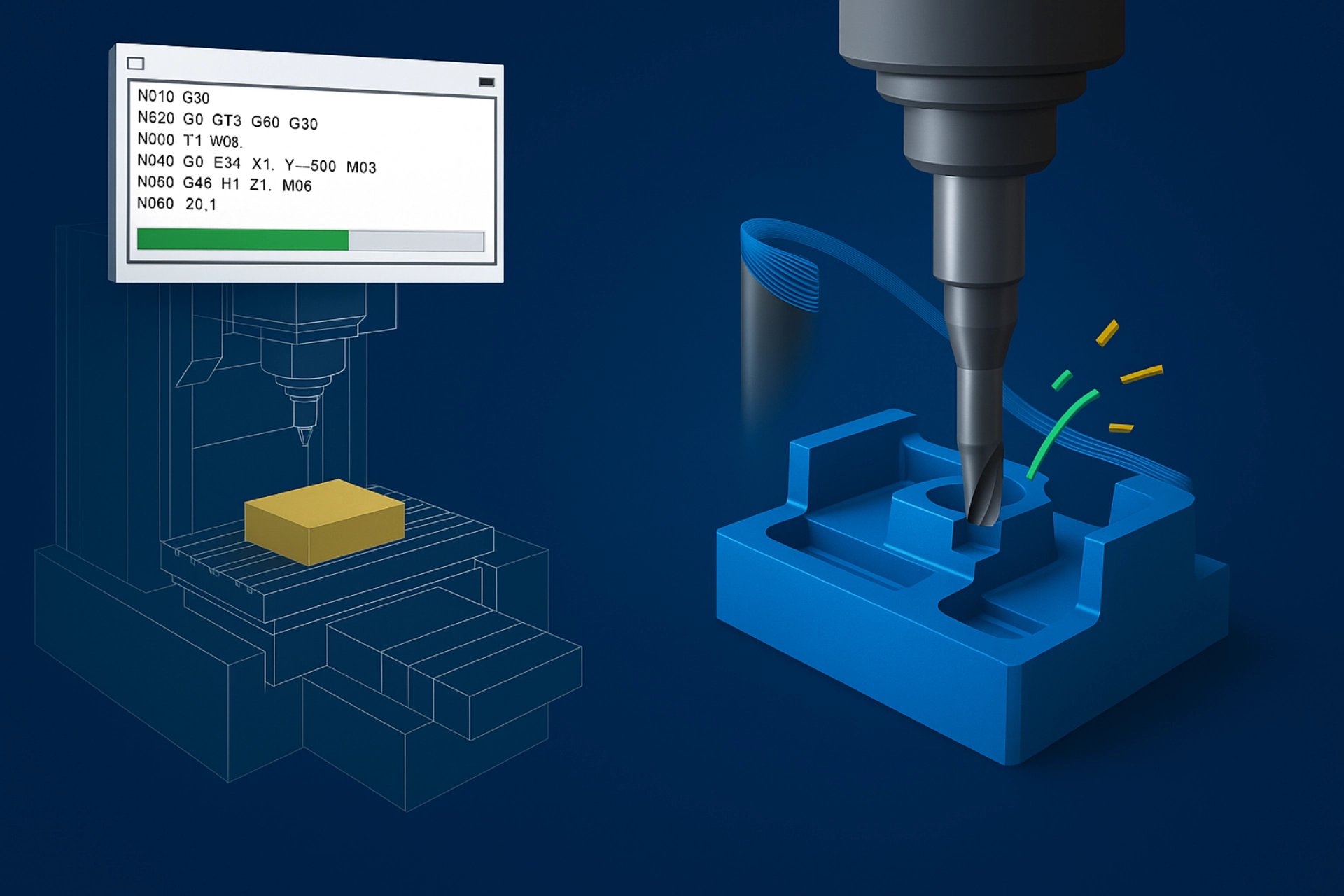

The solution: simulate before machining

This is where VERICUT comes into play, the leading independent CNC simulation tool. By accurately replicating the machine, the tool, and the cutting process in a virtual environment, VERICUT allows every detail of the NC program to be checked before it is sent to the shop floor.

In this way, errors never reach the real machine: they are detected and corrected during simulation. The result is safe, predictable machining with no unpleasant surprises.

The benefits of surprise-free manufacturing

Implementing VERICUT validation before cutting material delivers tangible benefits:

- Waste reduction: defective parts and unnecessary material consumption become a thing of the past.

- Machine protection: the risk of collisions that can damage critical components is minimized.

- Operator confidence: knowing the program has been validated in advance builds confidence and speeds up setup.

- Time savings: fewer machine prove-outs mean more productive hours spent manufacturing.

- Guaranteed quality: surface finishes and results meet required standards from the first run.

In short, simulating before machining is no longer a luxury, but a necessity for any company seeking efficiency and precision in its manufacturing process.

Do you want to take the step toward error-free and more profitable machining?

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177