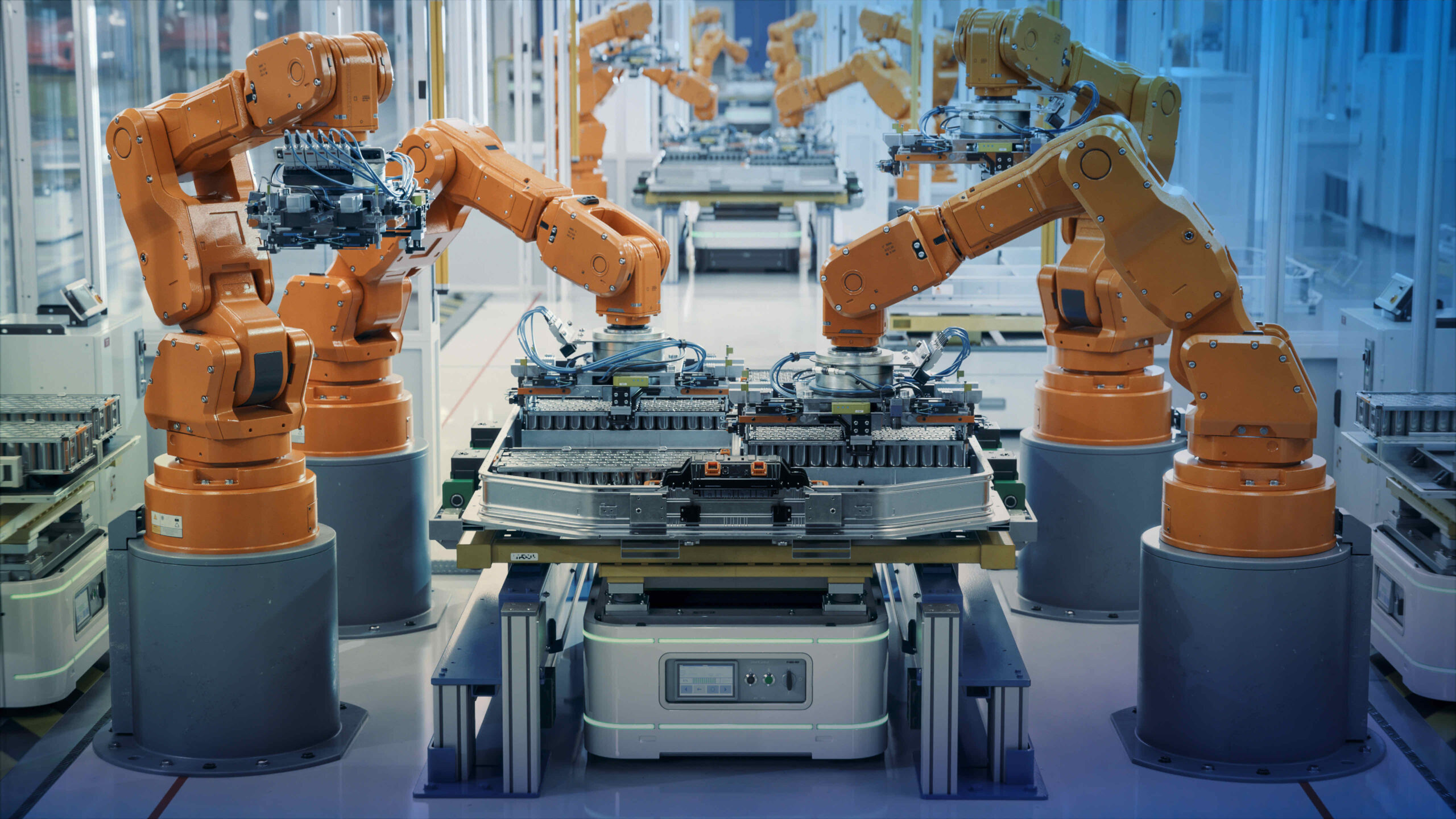

Integrating robots into complex production lines is not an easy task.

A small synchronization error, poorly defined logic, or an unexpected movement can result in hours of downtime and thousands of euros in losses. In an environment where efficiency makes the difference, testing before building is no longer an option—it is a necessity.

Robotics Virtual Commissioning makes it possible to validate and optimize the behavior of robots, sensors, and controllers in a connected virtual environment before physical commissioning. It is the natural evolution of Virtual Commissioning applied to robotic automation.

What is Robot Virtual Commissioning?

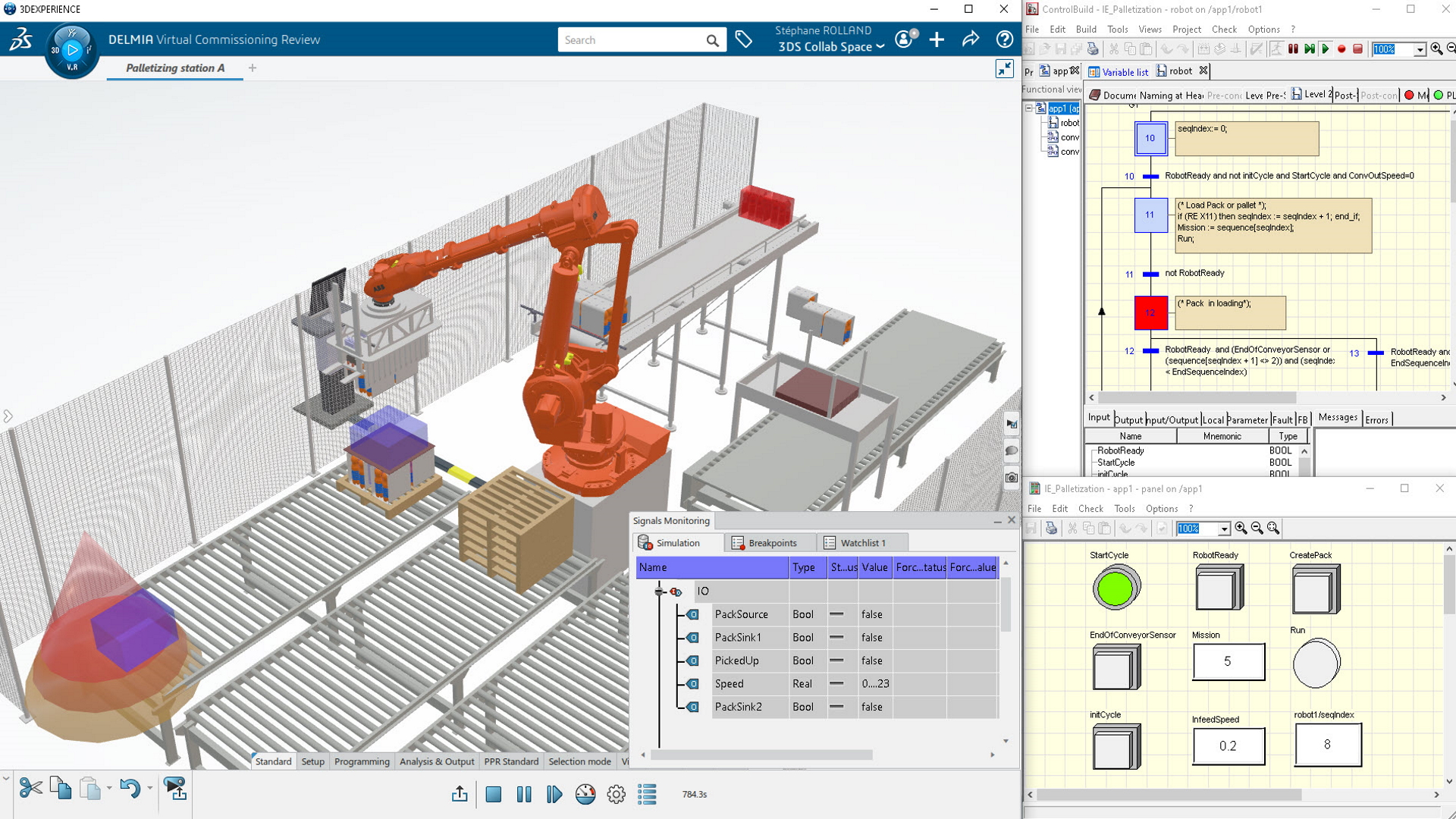

Robotics Virtual Commissioning (RVC) is a methodology that integrates the 3D model of a robotic cell with the control logic of PLCs and robot controllers, allowing the complete system behavior to be simulated before real installation.

Based on the DELMIA Robotics Virtual Commissioning Analyst (RVN) solution, available both on premise and in the cloud, it provides a digital environment where engineers can connect real or emulated controllers and validate control logic in real time.

This makes it possible to verify movements, toolpaths, and synchronization between robots and peripheral equipment with full accuracy, eliminating the typical risks of physical commissioning.

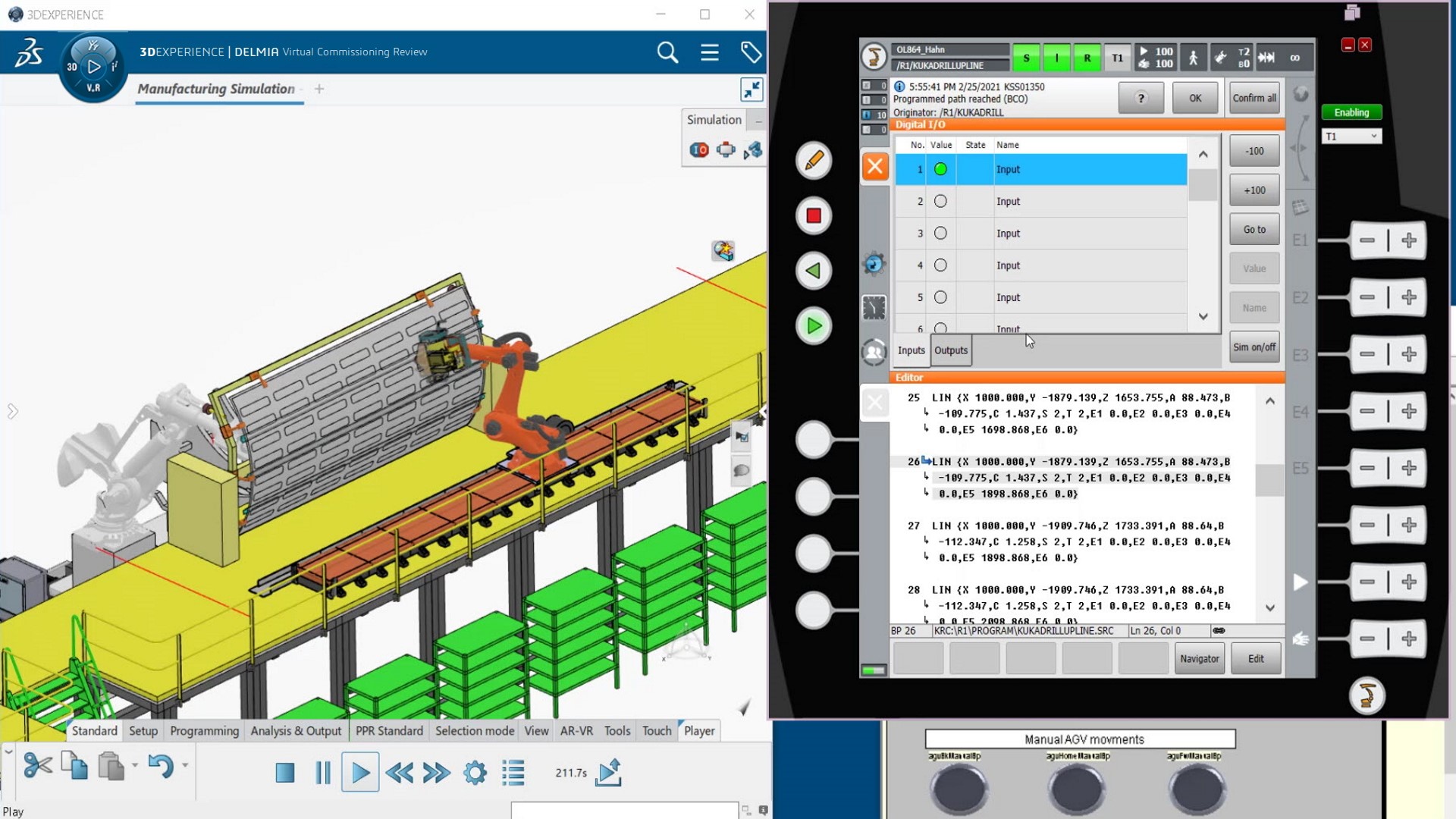

RVN enables virtual commissioning scenarios to be executed on a virtual twin, simulating robots and sensors connected to real PLCs through standards such as OPC-UA or RRS II.

How it works: full integration between robotics and control

Robotics Virtual Commissioning is based on direct integration between engineering, robotics, and automation, creating a digital replica of the complete system.

Its key capabilities include:

- Integration with CATIA ControlBuild to validate PLC logic and synchronize it with robot movements.

- Compatibility with RRS II and virtual controllers such as FANUC RoboGuide™, enabling realistic emulation of robot behavior.

- Use of the Virtual Teach Pendant, which reproduces the physical controller’s programming interface, enabling realistic and safe validation.

- Standard OPC / OPC-UA / FMU connectivity to integrate physical or simulated controllers into the simulation environment.

- Hardware-in-the-loop configurations, where real PLCs communicate directly with the virtual model, ensuring full fidelity to the system’s physical behavior.

Thanks to this integration, engineers can detect logic conflicts, collisions, or desynchronization issues before they occur, optimize programming, and drastically reduce commissioning time.

Operational and strategic advantages

Robotics Virtual Commissioning delivers tangible benefits at both technical and organizational levels:

- Early validation of control logic and robotic movements.

- Perfect synchronization between robots, conveyors, sensors, and auxiliary systems.

- Reduced commissioning time by avoiding errors during the critical startup phase.

- Training and upskilling of programmers and operators in a safe, realistic environment.

- Lower debugging and on-site adjustment costs.

- Increased reliability of automated systems from day one.

“Every cycle validated virtually is one less risk during real commissioning.”

In addition, validation in a virtual environment accelerates the integration of new robots or line upgrades, ensuring smooth implementation without disrupting ongoing production.

Connection with the production digital twin

Robotics Virtual Commissioning is part of the Manufacturing Virtual Twin concept, which brings together design, engineering, automation, and operations in a single digital environment.

Within the DELMIA 3DEXPERIENCE ecosystem, this approach allows the virtual model to evolve alongside the real one, ensuring full traceability and continuous process improvement.

If you want to understand how this practice fits into overall Virtual Commissioning, you can read our article:

Virtual Commissioning: the standard in industrial equipment manufacturing.

Use cases and sectors where it makes a difference

The benefits of Robotics Virtual Commissioning are especially visible in sectors where automation is critical:

- Automotive: validation of robotic cells for welding, painting, or assembly.

- Industrial machinery: synchronization between robots, linear axes, and conveyors.

- Electronics and consumer goods: precision in handling and assembling delicate components.

- Packaging and logistics: optimization of movements and cycle times.

Manufacturers and integrators already applying it not only reduce costs and time: they achieve greater reliability, predictability, and control over their automation projects.

Conclusion: virtual robotics as a guarantee of success

Robotics Virtual Commissioning is not a trend, but a cornerstone of modern robotic system design and validation.

It makes it possible to anticipate errors, ensure programming quality, and achieve a surprise-free startup.

In an industrial environment where flexibility and precision are essential, virtual validation is the key to producing with confidence from the very first cycle.

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177