For years, commissioning has been the most unpredictable—and costly—phase of any industrial project.

Endless hours of debugging, last-minute fixes, and improvised tests on the shop floor have turned this stage into a major production bottleneck.

Every issue detected too late leads to delays, cost overruns, and intense pressure to start up on time.

Today, the industry has found a way to anticipate this chaos: Virtual Commissioning—a methodology that makes it possible to simulate, test, and validate complete production systems in a digital environment before a single physical asset is installed.

Far from a future promise, it is a proven practice that already makes the difference between a controlled startup and one based on trial and error.

What Is Virtual Commissioning?

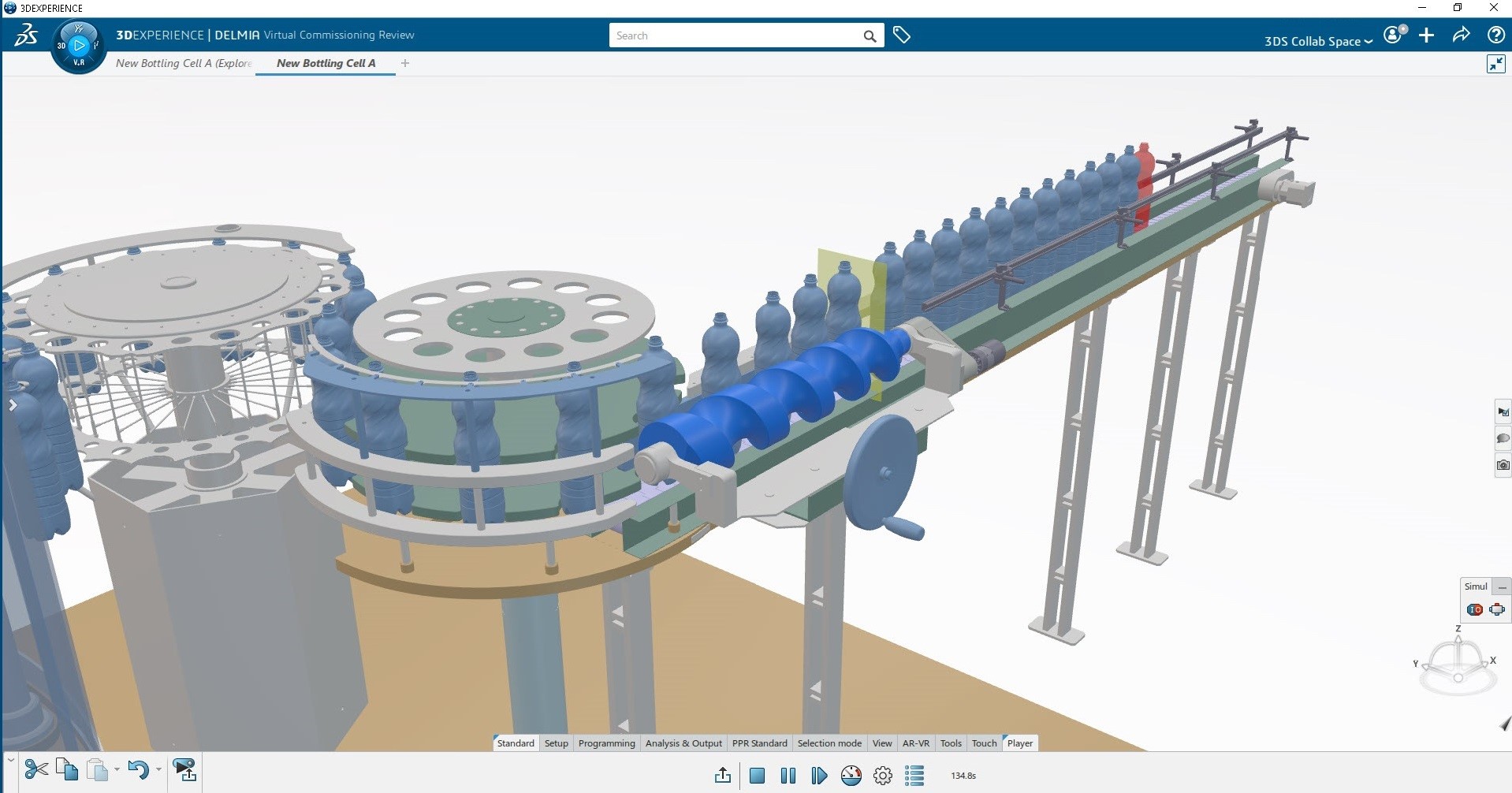

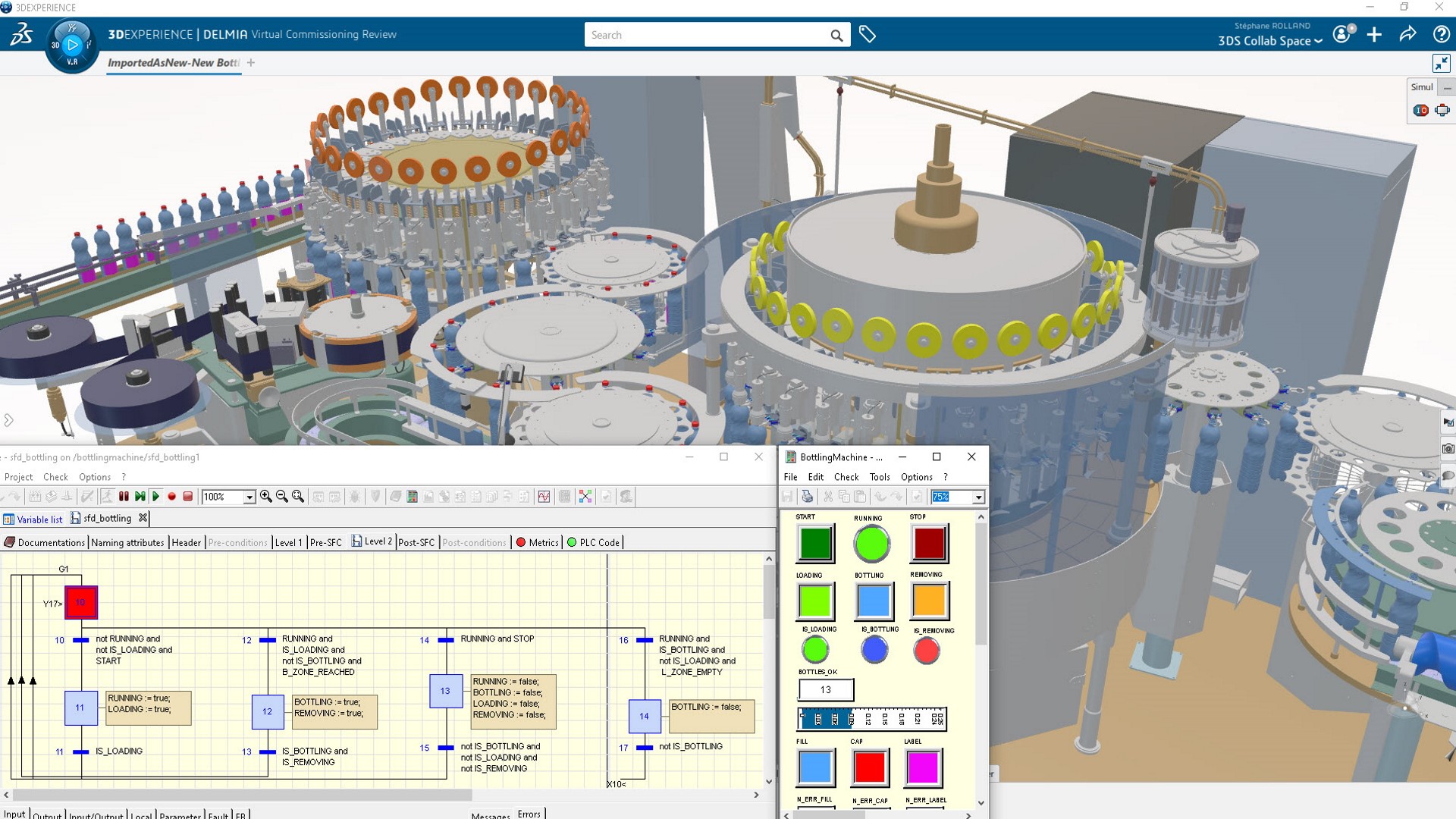

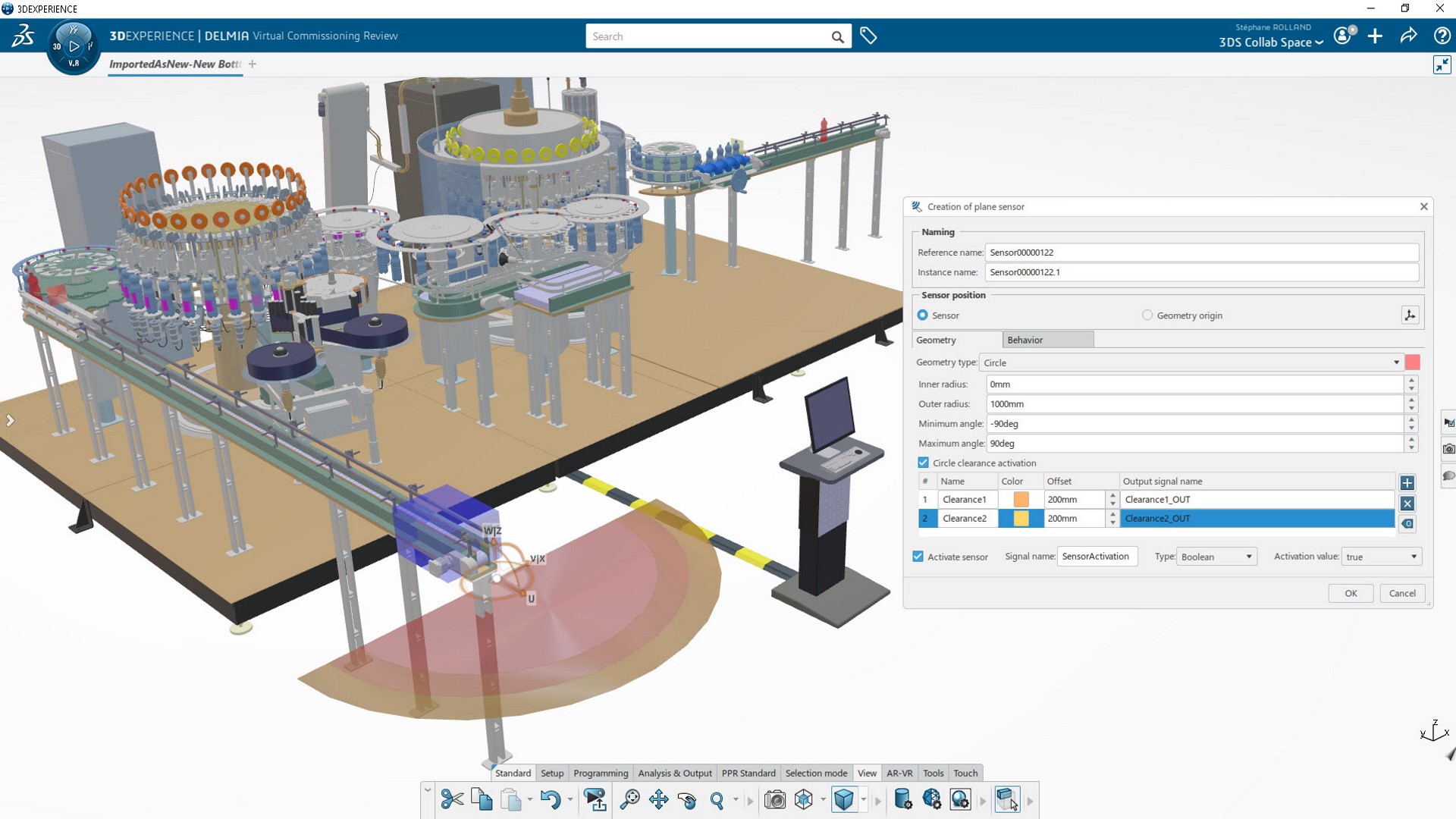

Virtual Commissioning consists of digitally replicating a production line, machine, or manufacturing cell by integrating its 3D model with the control program (PLC) and the electrical, mechanical, and automation systems.

With DELMIA Virtual Commissioning Analyst (VCA)—available both on premise and in the cloud—engineers can create a virtual twin of the production environment and connect real or emulated controllers to validate control logic and physical system behavior before commissioning.

The result: less uncertainty, less wasted time, and a predictable, safe startup.

Why Change the Traditional Approach?

The commissioning phase remains one of the biggest challenges in the lifecycle of a machine or production line.

Studies in the machine tool industry show that Virtual Commissioning can reduce commissioning time by up to 75%, minimizing errors, cost overruns, and delays detected during critical startup phases.

How It Works: Digital First, Physical Later

Virtual Commissioning shifts validation from the physical world to the digital one by combining three key elements:

- Detailed 3D models of machines, robots, and systems

- Simulation of sensors, actuators, and control logic with realistic behavior

- Direct integration with PLC programs through the native connector with CATIA ControlBuild

In addition, standard OPC and OPC-UA connectivity ensures secure, fast communication with physical or emulated controllers.

In advanced setups, the real PLC can even be connected to the virtual twin (hardware-in-the-loop) to validate the exact behavior of the installation before assembly.

Three Levels of Impact

Virtual Commissioning operates at different levels of the production system:

1. Plant Level

Enables validation of the complete production line, identification of inefficiencies, synchronization of robots and stations, and early detection of bottlenecks before they exist.

2. Machine Level

Optimizes coordination between mechatronic components, sensors, and actuators, ensuring each motion sequence works in harmony with the control logic.

3. Part or Material Level

Simulates component behavior under real operating conditions, ensuring reliability from the very first cycle.

Together, these three levels turn simulation into a tool for design, validation, and strategic decision-making.

Tangible Benefits for Industry

Adopting Virtual Commissioning delivers measurable advantages that directly impact profitability:

- Reduced risk by validating control systems before physical implementation

- Faster startups, with time reductions of up to 75%

- Elimination of late-stage errors through early PLC software validation

- Lower rework costs and budget deviations

- Operator training in safe, realistic environments without interrupting production

- Seamless integration with the production digital twin (Virtual Twin), the foundation of Dassault Systèmes’ smart factory vision

Every minute invested in virtual validation translates into hours saved during real commissioning.

From Advanced Simulation to an Industry Standard

What was once reserved for the most advanced manufacturers has now become an essential methodology for any company aiming to compete in a digital-first model.

Leaders in automotive, industrial machinery, and electronics already prove its value every day: faster projects, surprise-free startups, and higher operational reliability.

In a context where efficiency defines competitiveness, Virtual Commissioning is not an option—it is the modern way to manufacture with precision from day one.

Conclusion

Virtual Commissioning is far more than simulation—it is how the industry ensures quality and efficiency before investing in physical assets.

With DELMIA Virtual Commissioning Analyst, companies can integrate design, automation, and validation in a single collaborative environment on the 3DEXPERIENCE platform.

The factory of the future is no longer built first—it is validated before it exists.

Take the Next Step Toward Virtual Commissioning

At CADTECH, experts in DELMIA and 3DEXPERIENCE solutions, we help industrial companies implement Virtual Commissioning strategies that reduce risk, accelerate commissioning, and maximize production line efficiency.

Anticipate problems before they occur.

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177