Topological optimization is an advanced simulation technique that allows automatically generating optimized geometric shapes based on real usage conditions. Instead of starting from a traditional geometry, it proposes the optimal distribution of material while respecting load, displacement, and manufacturing constraints.

Topology optimization

Thanks to this technology, companies can reduce weight, save material, and improve product performance, accelerating development and boosting innovation from the earliest design stages.

Key areas and processes of topological optimization

Structural optimization

Enables the application of complex structural criteria, with multiple loads, contacts, or nonlinearities, to generate the most efficient possible shape.

Integration with advanced simulation

Works directly with simulation models in Abaqus and other CAE software, allowing high-precision optimization without the need to redesign from scratch.

Manufacturing constraints

Incorporates real technological conditions (protected areas, symmetry, pull directions, etc.) to ensure the solution can be manufactured.

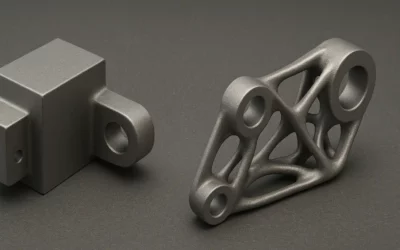

Preparation for additive or traditional manufacturing

The optimized geometry can be refined and adapted for 3D printing or for conventional machining or casting processes.

Parametric and non-parametric optimization

Structural optimization can be approached from two complementary perspectives: non-parametric optimization, which freely redistributes material to generate new shapes, and parametric optimization, which adjusts predefined variables such as thicknesses, radii, or positions within an existing geometry. This flexibility allows both designing from scratch and improving already-developed components, adapting the strategy to the project’s goals.

Significant mass reductions can be achieved without losing performance, improving product efficiency and reducing environmental impact.

It avoids long redesign and testing cycles by proposing optimal shapes from the initial simulation.

More robust, efficient designs adapted to real use, with lower risk of failure or overengineering.

It enables the exploration of new and disruptive shapes that are impossible to generate with traditional CAD tools.

Topological optimization with SIMULIA TOSCA

Tosca Structure is Dassault Systèmes’ solution for applying topological optimization—either freely or parametrically—directly on simulation models. It is based on the Abaqus solver and enables work with nonlinear load conditions, multiple objectives, and complex constraints.

It is a tool designed for simulation engineers who want to go beyond structural analysis and automatically generate highly efficient design proposals.