The Virtual Twin is a digital representation of a product, process, or system in its entirety, allowing simulation, analysis, and optimization of its performance in a digital environment before physical implementation.

Virtual Twin

Thanks to its ability to integrate real-time data, 3D modeling, and advanced simulation, the Virtual Twin enables companies to improve decision-making, reduce costs, and accelerate innovation across multiple industries.

Key Areas and Processes of the Virtual Twin

Product Design And Development

Optimization of design from the earliest phases, considering all factors before production.

Simulation And Validation

Virtual testing in realistic scenarios to improve performance and reduce risks before manufacturing.

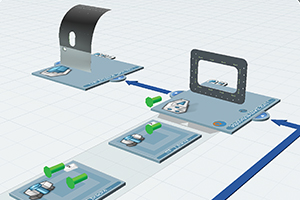

Production and Manufacturing

Planning and optimization of production processes through operations and logistics simulation.

Predictive Maintenance

Real-time analysis to anticipate failures, reduce downtime, and improve operational efficiency.

Sustainability and Product Lifecycle

Environmental impact assessment, materials optimization, and improvement in energy efficiency.

The Value of the Virtual Twin

Simulating and validating before producing prevents errors and optimizes resources.

Monitoring and continuous analysis to optimize processes in real-time.

Consolidation of information to anticipate problems and improve business strategy.

Testing in digital environments to accelerate the implementation of new technologies.

Reduction of waste and optimization of material use to minimize the environmental footprint.

The Digital Twin on the 3DEXPERIENCE Platform

The 3DEXPERIENCE platform from Dassault Systèmes enables a comprehensive implementation of the Digital Twin, connecting design, simulation, production, and operation in a collaborative environment. Thanks to its data-driven approach, companies can efficiently manage the entire lifecycle of their products and processes, reducing risks and improving competitiveness in an increasingly digitized world.

Discover here how to create and manage the virtual twin of your products in 3DEXPERIENCE