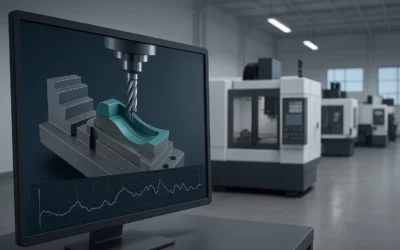

VERICUT Optimizer is a standalone solution designed to optimize toolpaths in CNC programs, improving efficiency without the need to use the VERICUT verification module. It is ideal for workshops looking to maximize machine performance without changing their current verification software.

VERICUT Optimizer

Maximize the efficiency of your CNC programs with autonomous optimization

Powered by the same technology as the VERICUT Force module, Optimizer provides detailed analysis and data-driven optimization strategies, allowing programmers to significantly improve cycle times and tool life.

Areas of use for VERICUT Optimizer

Optimization of existing NC programs

Improve current programs to reduce machining time and increase efficiency.

Integration with various CAM systems

Compatible with APT/CL-file or G-code outputs from almost any CAM system, making implementation easy in different environments.

Applications in 3- to 5-axis machines

Suitable for a wide range of CNC machine configurations, including complex 5-axis applications.

Benefits of VERICUT Optimizer

Significant cycle time reduction

Optimize cutting conditions to speed up the machining process.

Extension of tool life

Adjust cutting parameters to minimize tool wear.

Detailed analysis of cutting processes

Provides accurate information on cutting forces, torque, material removal, and more, enabling informed decision-making.

Easy implementation

Intuitive interface that makes it easy to set up and optimize programs in a few steps.

Enhance your CNC programs with VERICUT Optimizer

Contact us to discover how this tool can be integrated into your workflow and deliver tangible improvements in productivity and efficiency.

News and trends around VERICUT

Vericut Optimizer: autonomous CNC optimization for any CAM

A slight overload in a single pass, a barely noticeable vibration… and a €40,000 machining head ends up damaged. In another plant, a technician discovers that by reducing just half a gram per part in a run of 10,000 units, the company could have saved more than a week...

VERICUT 9.6: Power, Precision, and CNC Optimization in One Solution

In CNC machining, every detail matters. A single programming error can cost time, money, and even damage the machine. That’s why, for more than 35 years, leading companies have trusted VERICUT—the independent CNC simulation and optimization software that ensures safe,...

Machining smarter, not harder: how to extend tool life without sacrificing productivity

In CNC machining, the pressure to increase productivity often leads to using increasingly aggressive cutting parameters. In the short term it may seem like a solution, but the result is often the opposite: accelerated tool wear, higher risk of breakage, and unstable...