Product simulation is an essential tool in modern development, allowing companies to predict and optimize the behavior of their products under real-world conditions before manufacturing.

Product Simulation

By virtually replicating operating scenarios, organizations can identify and resolve potential problems, reduce the cost of physical prototypes, and accelerate time-to-market.

Key Areas and Processes of Product Simulation

Product simulation covers several fundamental areas:

Structural Analysis

Evaluates the strength and durability of materials and components under specific loads and conditions.

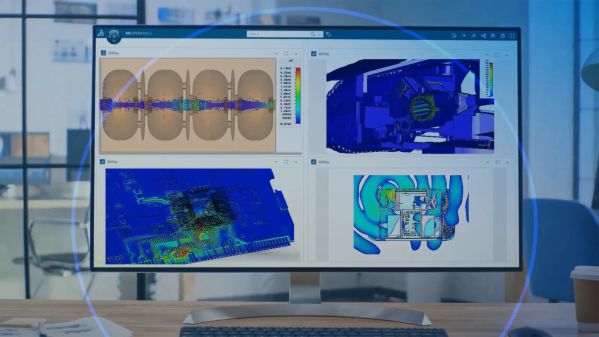

Electromagnetics Simulation

Analyzes the interaction of electromagnetic fields with products, crucial in the design of electronic devices and communication systems.

Fluid Dynamics Simulation (CFD)

Simulates the behavior of fluids and gases in interaction with solid surfaces, which is essential for industries like automotive and aerospace.

Thermal Analysis

Studies the distribution and management of heat in products, ensuring their optimal functioning and safety.

Multiphysics Simulation

Integrates multiple disciplines (mechanical, thermal, electromagnetic) to evaluate the complex behavior of products under real-world conditions.

Value of Simulation in Industry Beyond Design

Industrial companies face constant challenges in product development: slow iterations, lack of early validation, high costs due to errors in advanced stages, and difficulties in decision-making. Product simulation transforms these challenges into opportunities:

Early Validation and Error Reduction

Allows the testing and optimization of designs in virtual environments before manufacturing, minimizing failure costs and ensuring optimal performance.

Agility in Decision-Making

Provides precise and predictive data, facilitating strategic adjustments and reducing uncertainty at every stage of development.

Materials and Processes Optimization

Simulates real-world conditions to evaluate product behavior, helping to select the appropriate materials and improve manufacturing efficiency.

Reduced Dependence on Physical Prototypes

Reduces the need for costly and prolonged physical testing, accelerating the innovation cycle and time-to-market.

Regulatory Compliance and Total Traceability

Ensures that every product version complies with regulations and industry standards, maintaining a detailed history of modifications and results.

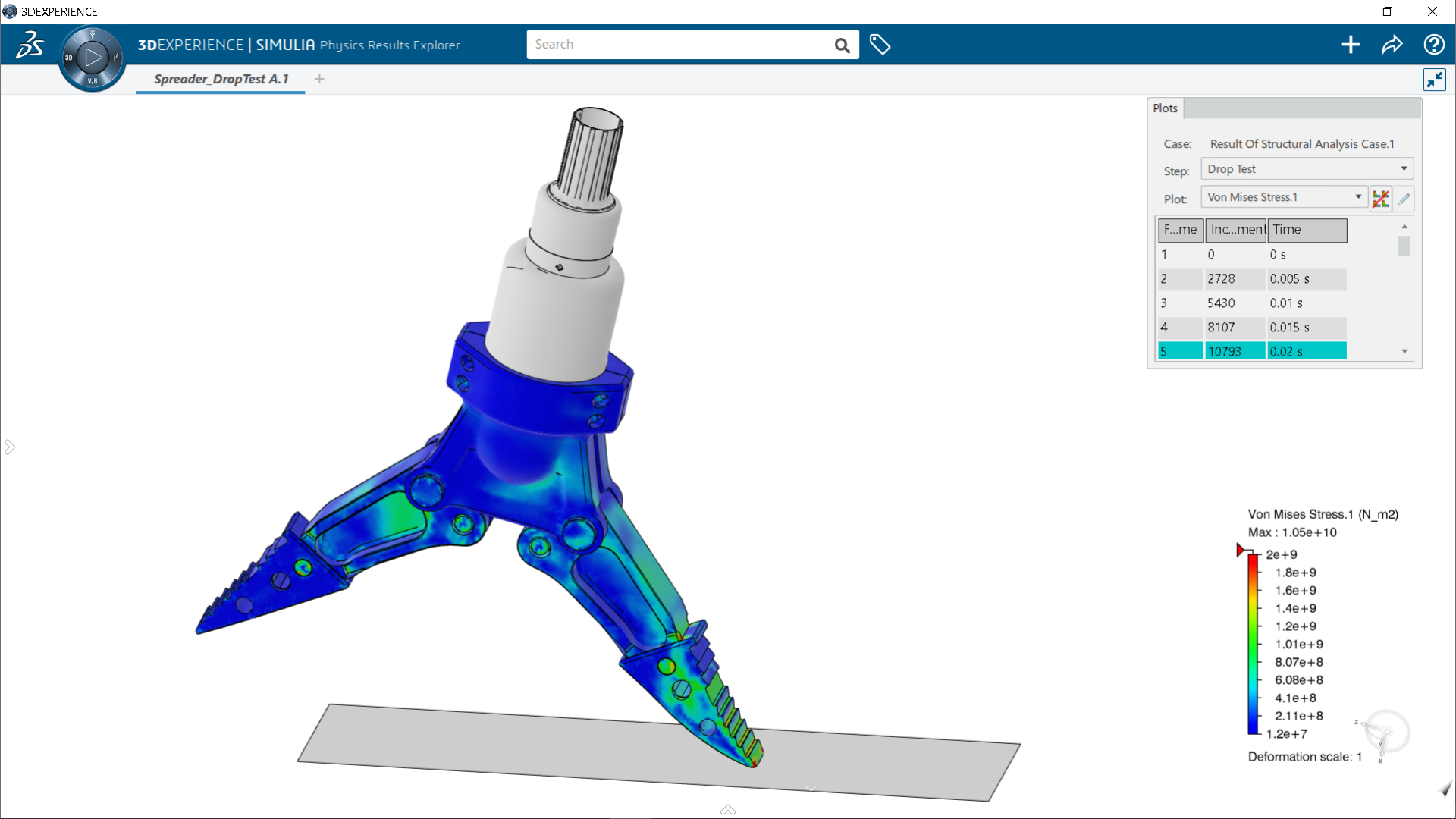

SIMULIA 3DEXPERIENCE: Power and Precision in Simulation

Integrated into the 3DEXPERIENCE Platform, SIMULIA provides an advanced simulation ecosystem that enables product optimization from the earliest design stages. With leading tools such as Abaqus for structural analysis, CST Studio Suite for electromagnetic simulations, and XFlow for fluid dynamics, companies can evaluate product performance under real conditions before manufacturing — reducing risks, costs, and development time.

This capability is driven by MODSIM, an approach that unifies modeling and simulation within a single environment, eliminating data silos and enabling faster, more efficient iterations. Only with SIMULIA 3DEXPERIENCE can these processes be seamlessly integrated, ensuring greater model accuracy and better-informed decision-making.

Discover here how SIMULIA 3DEXPERIENCE can elevate your product simulation and optimize your processes.