DELMIA, a solution from Dassault Systèmes, provides advanced tools for the simulation and optimization of manufacturing processes. Its approach enables companies to model and improve their operations, ensuring more efficient, flexible production aligned with quality standards.

DELMIA

Advanced simulation of manufacturing processes

From process planning to ergonomics and logistics, DELMIA helps anticipate and solve manufacturing challenges. By integrating design, simulation, and execution in a digital environment, it enables more agile and accurate decision-making, ensuring more sustainable and competitive operations.

Key areas of digital manufacturing with DELMIA

Ergonomics and human factors simulation

Ergonomic assessment: DELMIA Ergonomics allows analysis of the interaction between workers and their work environment, identifying ergonomic risks and improving workplace safety and comfort.

Human task simulation: Through DELMIA Human Task Simulation, worker movements and postures can be evaluated, optimizing workstation design to increase productivity and reduce injuries.

Simulation of logistics and material flows

Material flow simulation: DELMIA Logistics Simulation helps plan and simulate material flows within the plant, optimizing inventory management and ensuring efficient supply at every stage of production.

Internal transportation system modeling: With DELMIA Transportation and Logistics Planning, it is possible to simulate and optimize the transport and distribution of materials inside and outside the facilities, improving both internal and external logistics.

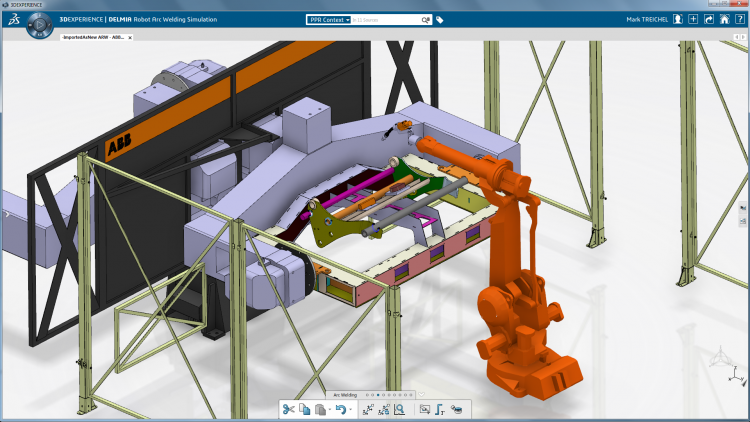

Simulation of welding processes

Welding process simulation: DELMIA Welding Simulation allows modeling and analysis of welding processes, evaluating distortions and residual stresses to improve the quality and durability of joints.

Simulation of painting and coating processes

Painting process simulation: DELMIA Paint Shop Simulation helps plan and optimize painting and coating processes, ensuring uniform coverage and reducing material waste.

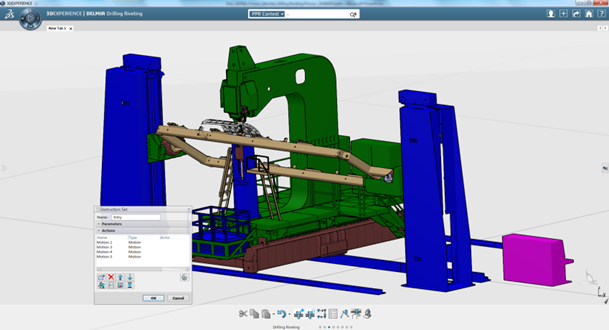

Production planning and optimization

Manufacturing process planning: with DELMIA Process Planning, companies can design and optimize their production processes before execution, reducing costs and development time.

Production and capacity planning: DELMIA Production Scheduler enables synchronization of resources, machinery, and materials, ensuring efficient production aligned with demand.

Benefits of implementing DELMIA

Improvement of operational efficiency

By simulating and optimizing processes, companies can identify and eliminate inefficiencies, reducing cycle times and operational costs.

Improved product quality

Simulation makes it possible to anticipate and correct potential defects in manufacturing processes, ensuring high-quality products.

Reduction of occupational risks

Ergonomic assessment and human task simulation help design safer work environments, reducing the risk of injuries and improving employee well-being.

Optimization of internal logistics

Simulation of material flows and internal transportation systems enables more efficient supply chain management, reducing inventories and delivery times.

DELMIA: simulation for smarter manufacturing

By adopting DELMIA’s simulation solutions, companies can transform their manufacturing processes, achieving greater competitiveness and adaptability in an ever-evolving market.

Discover how DELMIA’s simulation solutions can transform your manufacturing processes, improving efficiency, quality, and safety in your company. Contact us for more information.

News and trends around DELMIA

CADTECH will be present at MWC 2026 alongside Dassault Systèmes

From March 2–5, 2026, Dassault Systèmes will participate in Mobile World Congress in Barcelona (Hall 4 – Booth 4B25), where CADTECH will also be present, showcasing how connectivity, industrial artificial intelligence, and Virtual Twins are redefining the way...

CAF: driving sustainable mobility with 3DEXPERIENCE

(Photo © CAF) The transition from diesel to electric trains is already a reality in Europe. In this context, CAF is involved in projects such as the development of Civity BEMU trains in Germany, contributing to significantly reducing CO₂ emissions and promoting a more...

Airbus Helicopters: From Design to Certification in 3DEXPERIENCE

(Photo © AIRBUS)In helicopter development, there are no minor decisions. Every design choice directly impacts the performance, safety, and reliability of a machine that must operate in extreme environments—from dense urban areas to remote mountainous regions. Added to...