Imagine an industrial machinery company launching a new electromechanical equipment model designed to revolutionize its target market. To achieve this, they have implemented an automated production line with robots and transport systems. However, during commissioning, unexpected issues arise: robots and conveyors are not perfectly synchronized, control systems show errors, and deadlines begin to slip. This increases costs and puts the launch of a key product at risk.

These challenges demonstrate how difficult it can be to integrate advanced technology into manufacturing processes. In such a competitive environment, companies need fast and effective solutions that allow them to reduce time to market and maintain their market position.

The impact of delays on time to market

Not optimizing time to market can have serious consequences, such as:

- Loss of competitiveness: Other companies may launch innovative products first.

- Increased costs: Fixing issues during physical production is far more expensive and time-consuming.

- Customer dissatisfaction: Delays can damage trust and impact key business relationships.

- Loss of revenue: Every day of delay reduces the expected return on investment.

In a sector where every second counts, minimizing these risks is not optional—it’s essential to remain competitive.

Virtual commissioning: A revolutionary solution with DELMIA 3DEXPERIENCE

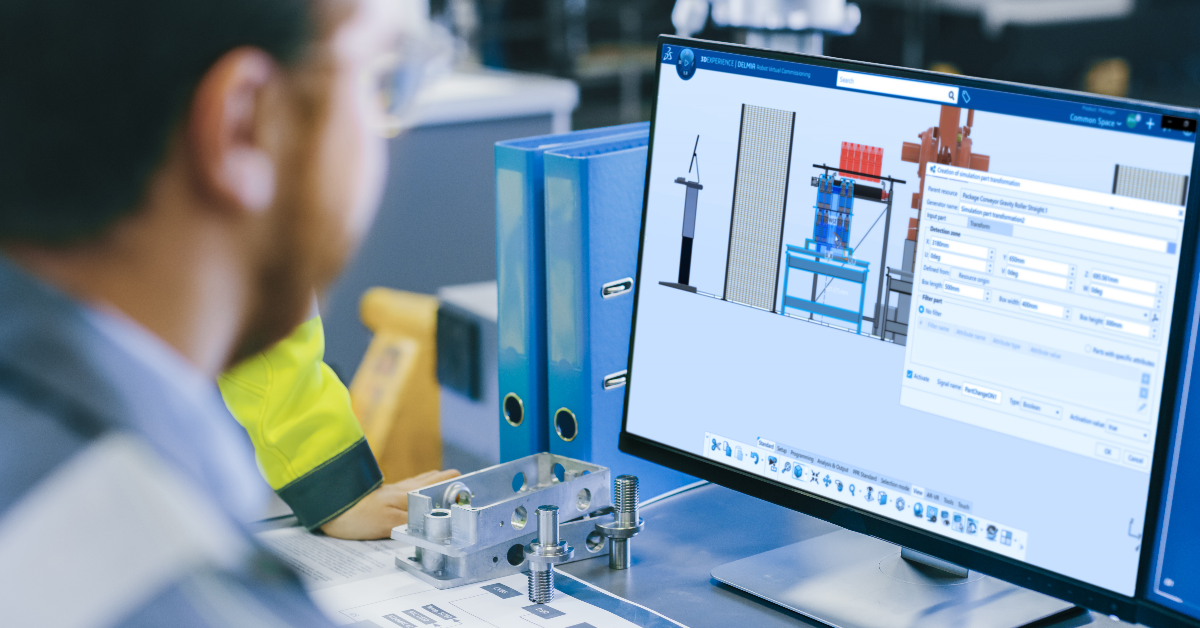

Virtual commissioning allows companies to simulate, test, and optimize their production lines in a virtual environment before implementing them physically and speeding up time to market. Using DELMIA technology on the 3DEXPERIENCE Platform, manufacturers can address integration issues with precision and efficiency.

With this technology, companies can:

- Detect design errors early: Simulate the interaction between robots, conveyors, and control systems to fix problems before they occur.

- Accelerate commissioning: Optimize processes virtually, significantly reducing the time and cost of physical adjustments.

- Enhance collaboration: Multidisciplinary teams work on a common model in real time, avoiding confusion and last-minute changes.

- Test alternative scenarios: Experiment with different configurations to find the best solution without stopping real production.

Tangible benefits of virtual commissioning

Companies that adopt virtual commissioning often report clear results:

- Faster launches: Up to a 25% reduction in commissioning time.

- Efficient use of resources: Less investment in physical adjustments and more time to focus on innovation.

- Greater reliability from day one: Production lines operate efficiently from the very first day.

- Competitive advantage: Meeting deadlines strengthens customer trust and secures key contracts.

For example, an industrial machinery company that implemented DELMIA 3DEXPERIENCE was able to detect synchronization issues and adjust the interaction between all elements of its production line before physical installation. As a result, they met critical deadlines, reduced costs, and strengthened their position in the market.

Conclusion

In a world where time is a limited resource, manufacturers face increasing pressure to accelerate their launches without compromising quality. The virtual commissioning with DELMIA 3DEXPERIENCE from Dassault Systèmes is te key tool to achieve it, enabling a more agile and safer integration. With this technology, companies not only optimize their processes but also lead their markets with confidence and efficiency.

CADTECH Communications Department

comunicacion@cadtech.es – 800 007 177