TOSCA is the non-parametric optimization solution within the SIMULIA portfolio, designed to accelerate the development of lighter, stronger, and more efficient products. Based on FEA and CFD simulations, it enables the exploration of innovative designs without starting from a predefined geometry, thanks to powerful topology, shape, bead (surface reinforcement), and sizing optimization algorithms.

TOSCA

Efficient optimization based on FEA and CFD simulations.

TOSCA works directly on the finite element mesh, without the need for CAD remodeling. It is available as a standalone solution or integrated into the 3DEXPERIENCE platform, and it enables performance maximization, material usage minimization, and reductions in weight, cost, and validation time for structural and flow components.

Key features of TOSCA

Topology optimization without CAD reconstruction

Works directly on the finite element mesh, avoiding the geometric remodeling process and accelerating design cycles.

Weight reduction while maintaining structural integrity

Identifies areas where material does not provide structural value so it can be removed, ensuring lighter components that are just as safe.

Lower material usage and production cost

Reduces material consumption from the initial design stage, promoting more sustainable and cost-effective manufacturing processes.

Improved structural performance from early stages

Enables optimization of the product’s shape and strength from the conceptual phase, reducing errors and subsequent rework.

Seamless integration with Abaqus and 3DEXPERIENCE

TOSCA results integrate easily with simulation and collaboration environments such as Abaqus and the 3DEXPERIENCE platform, enabling full traceability.

Benefits of topology optimization with TOSCA

More innovative designs from the conceptual phase

Enables the creation of entirely new shapes driven by structural performance.

Fewer iterations, greater agility

Reduces cycles between design, simulation, and validation, optimizing the entire process.

Weight reduction without compromising safety

Ideal for sectors seeking efficiency without sacrificing structural integrity.

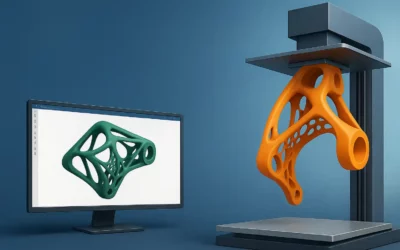

Preparation for additive manufacturing

Generates complex structures optimized for 3D printing or advanced manufacturing.

Improved performance under fatigue or cyclic loads

Increases the service life of components exposed to repetitive stresses.

Types of optimization with TOSCA

TOSCA technology makes it possible to apply different optimization approaches, adapted to each structural or flow design need:

Topology optimization

Explores entirely new designs based on functional constraints, without an initial geometry.

Shape optimization

Adjusts existing geometries to reduce stresses and improve durability.

Bead (surface reinforcement) optimization

Adds stiffness to sheet metal components without increasing weight.

Flow optimization (Fluid Flow)

Designs more efficient flow channels, improving the performance of fluid dynamic systems.

Industrial challenges addressed by TOSCA

-

Reduce component weight without compromising safety.

-

Minimize the number of iterations between design and simulation.

-

Optimize parts for additive manufacturing or 3D printing.

-

Increase the service life of components subjected to cyclic loads.

-

Avoid overdimensioning and unnecessary costs.

-

Develop more sustainable and efficient products from the design stage.

Topology optimization in 3DEXPERIENCE

The integration of TOSCA with the 3DEXPERIENCE platform brings optimization into a collaborative environment, connected to design, simulation, and manufacturing. This enables faster, data-driven decision-making with full traceability and no loss of information.

-

Collaborative and integrated environment

-

Centralized management of models and results

-

Cloud-based access to TOSCA through SIMULIA roles

Turn optimization into a competitive advantage from the very first design.

News and trends around TOSCA

TOSCA and generative design: structural optimization for a sustainable future

In the race to innovate, industrial companies seek not only to improve the performance of their products, but to do so responsibly. Sustainability is no longer a slogan: today it is a decisive criterion for winning projects, complying with regulations, and meeting new...

What is non-parametric optimization and why is it revolutionizing engineering?

Most engineers are used to optimizing their designs by modifying parameters: lengths, radii, thicknesses… But what if there were a way to optimize without relying on CAD? That is the basis of non-parametric optimization, and solutions like SIMULIA’s TOSCA are proving...

From generative design to additive manufacturing: the key role of topology optimization

3D printing has opened up new design possibilities. But… are you really taking full advantage of its potential? If you design the same way as always and only change the manufacturing method, you are missing out on a major advantage. One of the greatest allies of...